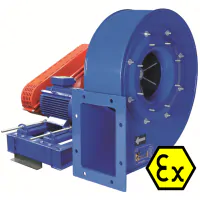

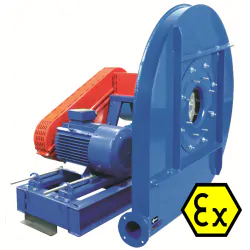

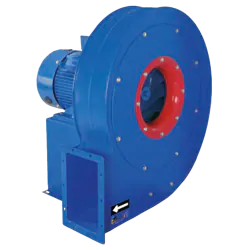

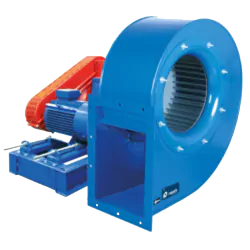

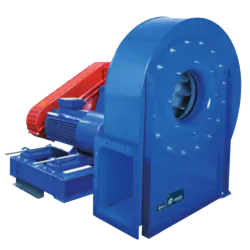

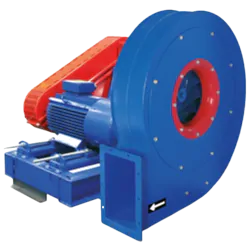

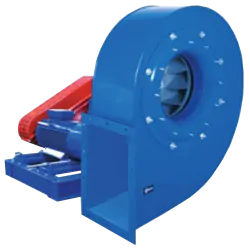

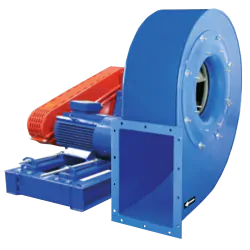

ATEX Centrifugal Fans

High Pressure Explosion Proof ATEX Certified Centrifugal Fans

Suitable for a wide range of potentially explosive environments, the award winning Casals range of ATEX centrifugal fans features over 38 models of industrial centrifugal fans, with multiple configurations and customised options for each.

The correct ATEX centrifugal fan will avoid instances where the fan becomes a source of ignition and reduces the risk of an explosion occuring in the presence of potentially dangerous gases and dusts. Ignition from choosing unsuitable ATEX fans can be a result of inadequate motor protection, conflicting materials rubbing friction or static electricity to name just a few instances. Choosing an industrial fan partner who has the technical skills in fan selection and fan integration will help to ensure your ATEX fan is safe for use and application in hazardous environments.

Our expert team are certified to supply ATEX fans and their necessary components in line with relevant ATEX Directive 2014/34/EU as implemented into UK legislation following Brexit.

Hazardous Area Classifications - A Key Part of ATEX Fan Selection

ATEX zones are classifications that determine the presence of the explosive gas or dust. This is then used to determine the level of protection the equipment must offer to be deemed suitable for use, ensuring it does not act as an ignition source in potentially hazardous environments.

Zone 0 Gas and Zone 20 Dust - Category 1G/1D

This zone signifies an area in which an explosive mixture is continuously present, or present for long time periods. We do not supply industrial fans within zone 0 or 20.

Zone 1 Gas and Zone 21 Dust - Category 2G/2D

This zone signifies an area in which an explosive mixture is likely to occur in normal operation. Our ATEX metal fans are available in both zone 1 and 21.

Zone 2 Gas and Zone 22 Dust - Category 3G/3D

This zone signifies an area in which an explosive mixture is not likely to occur in normal operation, and if it does, it will only exist for a short time.

We supply both metal and polypropylene fans in zone 2 and 22.

ATEX is An Ever Evolving Concept, Choose a Fan Supplier Who Will Enhance Your ATEX Fan Selections

The Axair team have undertaken extensive training in ATEX regulations but have a duty of care to ensure we supply a suitable fan based upon a customer’s correct ATEX coding specifications. ATEX has to be understood as an ever-evolving subject requiring competence and training that is now provided by UK notified bodies and consultancies. We advise that if anyone requires additional training in ATEX that they contact an independent body for assistance. Axair can supply fans suitable for ATEX applications within zone 1 & zone 2 manufactured from either metal or corrosion resistant polypropylene depending on the specification. To help with your understanding of ATEX atmospheres and accurate fan selection, view our article featuring the main ATEX concepts, here.