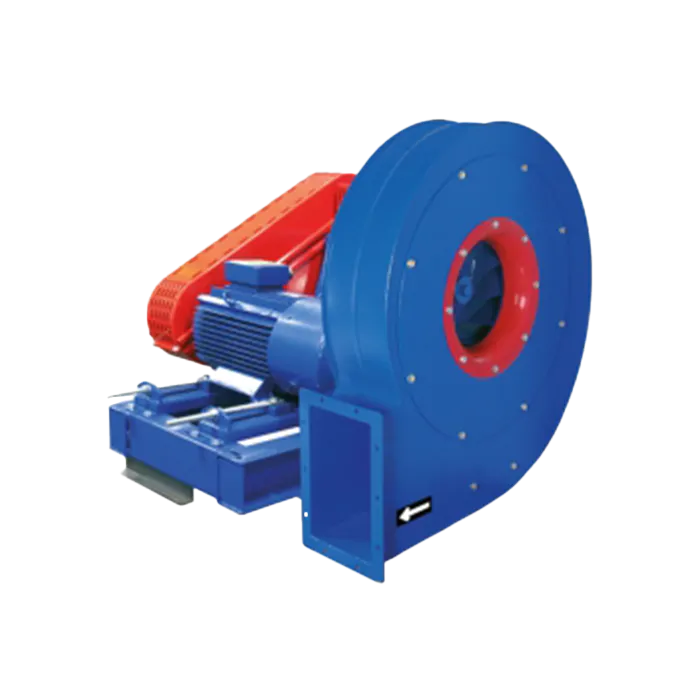

AATVG/N High Pressure Belt Driven Fans

Available in Standard and ATEX Versions

Manufacturing Features:

Centrifugal fan made of Fe360 sheet steel.

Fully welded housing finished with a qualicoat polyester powder coating stoved at 200ºC, with an average film thickness of 70 microns. Average heat resistance of the coating is 180ºC with peaks of 200ºC.

High efficiency simple inlet backward impeller with self-cleaning system made of Fe360 sheet statically and dynamically balanced. Impellers are painted with polyester primer that resists temperatures up to 300ºC.

Motorised fan with base frame.

Fully equipped fans including: motor, pulleys, belts, belts guard and shaft guard.

IE4 motors for 75kW power or higher.

Standard orientation LG270. The orientation can be adjusted with models 450 to 630. For model sizes 710 to 1000 the orientation is fixed.

Ideal for High Pressure Industrial Applications

AATVG/N belt driven fans are designed for inline installation and suitable for a range of high pressure applications including cooling of machines and parts, extraction or injection of air, pneumatic transport, slightly dusty air transport and exhaust after filters, separators and cyclones.

AATVG/N: Centrifugal belt driven fan with backward curved impellers

AATVG/N ATEX: ATEX versions![]()

Designed for inline installation, they are suitable for:

• Industrial applications, extraction or injection of air

• Cooling of machines and parts

• Exhaust after filters, separators and cyclones

• Pneumatic transport

• Slightly dusty air transport

• Maximum working temperature: carried air: 200ºC, ambient: 60ºC

• Fans for 60Hz and special voltages

• 2 speed motor

• Fan with free shaft or with motor supported on the pedestal side

• C4 or C5 paint coating

• Hot dip galvanised

• Special steel (Cor-Ten A, Hardox...)

• Inox 304 (normal or electropolished finish)

• Inox 316 (normal or electropolished finish)

• Cooling wheel

• Anticaloric paint

• Reinforced housing

• Fully welded housing (waterproof)

• Insulated housing

• Split casing (for big sizes)

• Inspection door to facilitate maintenance and cleaning

• Drain plug

• Airtight axle

• Frontal foot

• Double suction flange

• Available in non-sparking air passage and standard motor

• Other brands of motors

• Orientation: LG270, LG0, LG45, LG90, LG135, LG180, LG225, LG315, RD0, RD45, RD90, RD135, RD180, RD225, RD270, RD315

Technical Data

AATVG/N motorised fans are fitted over a base plate and fully equipped including; motor, pulleys, belts, belts guard and shaft guard. IE4 motors are available for 75kW power or higher.

| Fan Type | Voltage (V) |

Frequency (Hz) |

Input Power (kW) |

Rated Current (A) |

Speed (rpm) |

Max Temp (°C) |

IP Rating (IP) |

|---|---|---|---|---|---|---|---|

| GKHM 355-CIG.102.5HF IE Gen3 (IE5) | 3~ 380-480 | 50 / 60 | 2.33 | 3.7 at 400V | 3120 | 40 | IP54 |

| GKHM 400-CIG.114.6FF IE Gen3 (IE5) | 3~ 380-480 | 50 / 60 | 4.48 | 7 at 400V | 3170 | 40 | IP54 |

| GKHM 450-CIG.128.6IF IE Gen3 (IE4) | 3~ 380-480 | 50 / 60 | 5.9 | 9.05 at 400V | 2950 | 40 | IP54 |

| GKHM 500-CIG.143.6NA IE Gen3+ (IE4) | 3~ 380-480 | 50 / 60 | 7.48 | 11.4 at 400V | 2625 | 40 | IP54 |

| GKHM 560-CIG.160.6NA IE Gen3+ (IE4) | 3~ 380-480 | 50 / 60 | 6.85 | 10.7 at 400V | 2125 | 40 | IP54 |

| GKHM 630-CIG.180.6NA IE Gen3+ (IE4) | 3~ 380-480 | 50 / 60 | 5.1 | 7.88 at 400V | 1580 | 40 | IP54 |