EC Plug Fans

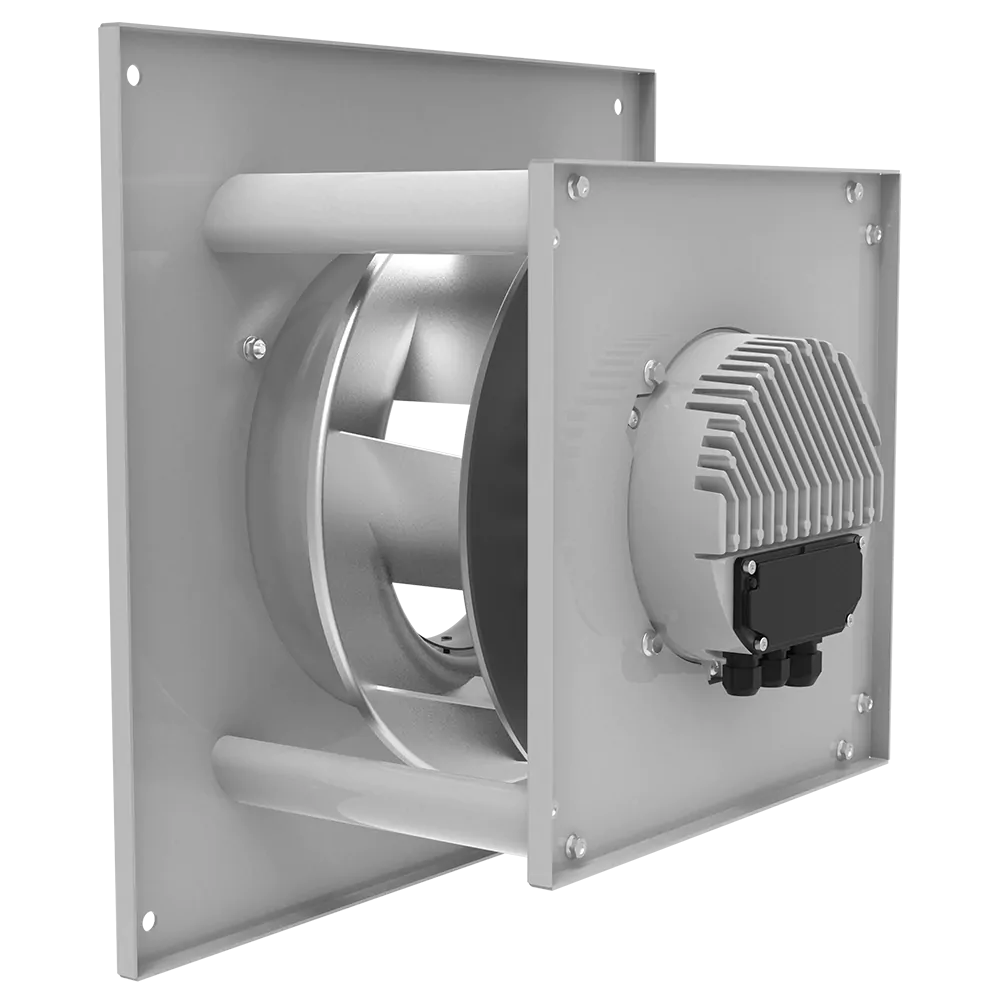

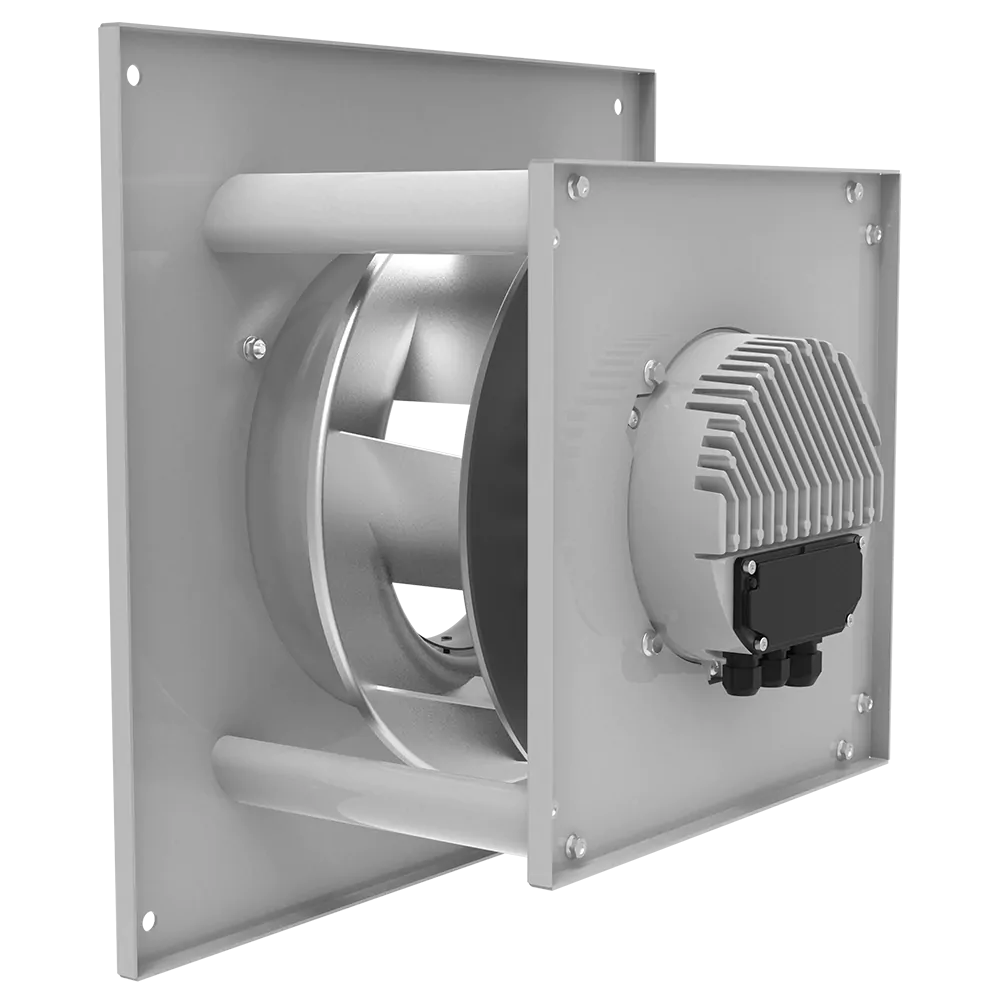

Motorised Impellers or Modular Backward Curved Plug Fans

We specialise in helping you to integrate the right EC plug fan into your system. Talk to our engineers about your application requirements or issues, and we'll work with you to overcome them, selecting the best fan for your specific requirements.

Our most popular Rosenberg EC plug fans, whether in motorised impellers without housing configurations (GKHR), or in module configurations (GKHM), feature innovative and highly efficient generation 3 or 3+ EC motors to motorise four variants of lightweight, and aerodynamically designed backward curved impellers.

Each of the four impeller series is designed in-house with the German engineering excellence found within the globally recognised fan manufacturer, The Rosenberg Group. Extensive research is undertaken to ensure impellers are designed with key consideration for their integration and use in core industrial fan air movement applications, ensuring final components are optimised for superior noise attenuation, energy efficiency, and performance.

This allows you to choose an impeller series that complements your system priorities perfectly; airflow, pressure, specific fan power, energy efficiency, compactness and more.

Powered by Gen 3 EC Motors for Performance and Efficiency.

Competitively priced Rosenberg EC plug fans are a cost effective, low noise solution that are used by many UK original equipment manufacturers in a wide range of market sectors including air handling units, containment and MVHR.

200-480VAC 3~ Supply.

Previous EC motor generations were designed for either 200-230VAC or 380-480VAC input power which required manufacturers to inventory both. Our new motor automatically adjusts to the actual input power across the entire range, allowing for reduced inventory cost.

280-680VDC Power Supply.

Motor automatically adjusts from AC to DC-input voltage when required in data centers or in back-up battery applications.

Gen 3 and Gen3+ motors are only on 3~ fans. 1~ fans feature Gen 2 motors.

Unmatched ModBus RTU functionality.

The motor monitors its current power consumption, and records total energy consumption, load profile, and fan operating temperature over time. This simplifies performance optimisation and preventive maintenance.

Electronic Quick-Change Technology (EQC).

The motor’s electronic head can be replaced within minutes without touching other parts of the fan.

IT-network (Earthing system) support for increased system fault tolerance, especially for hospitals and data centers.

These functions and capabilities are built into the Rosenberg Gen 3 motor, providing more information, communication and preventive maintenance planning capabilities, in addition to the new motor’s increased power and efficiency. Rosenberg’s advanced electronics provide users with a level of control and reliability never before available.

Rosenberg’s new Gen 3 EC motor offers users more sophisticated air movement for mission critical applications. It provides greater air movement power and electrical efficiency, advanced ModBus RTU functionality, built-in preventive maintenance and reliability features (Integrated inspection LED, Electronic Quick-Change capability, IT network support), and increased failure safety.

The “Generation 3” EC motor from Rosenberg achieved runner up in the AHR 2020 Innovation Awards competition. The fan motors are used to drive axial fans and backward curved impellers in environments where power, reliability and control are critical.

Part of Rosenberg’s innovation is advanced manufacturing technology that allows 40% more motor winding density creating 20-30% increased power in the same footprint. Also unique are the sophisticated electronics built-in for communication, control and greater reliability.

The new motors are 100% speed controllable and are CE, UL-R, and RoHS approved.

All EC plug fans are designed and manufactured meticulously to the highest standards by The Rosenberg Group in Germany. Learn more about Rosenberg here.

EC Plug Fans with I Impeller

Optimised for High Airflow

The latest high efficiency, high volume airflow orientated i-impeller features 5 backward curved, hollow profiled, aerofoil section blades, contoured in sheet aluminium. The new design significantly reduces the turbulent downstream air produced by traditional backward curved impellers. The effect of this reduction is significantly reduced noise and increased in-application efficeincy. I-series EC plug fans are optimised for high airflow applications.

I series blades are positioned diagnonally and top flared to enable the discharge airflow airflow direction to be optimised for the highest efficiency and flow rates.

Aluminium (AIMg3) motorised impeller, statically and dynamically balanced according to DIN ISO 21940-11 at least with quality level G6.3.

View the I series product page to see how using a smaller impeller with a smaller motor can result in a cost saving of up to 10% when compared with the B series under very similar operating characteristics.

The effect of reduced turbulent downstream air is a significant reduction in noise and increased in-application efficiency. the i-series offers a significant reduction in sound compared with the high pressure B series.

EC Plug Fans with B Impeller

Optimised for High Pressure

Optimised for high pressure applications, the B-series range of EC plug fans feature a seven alunimium blade design with a unique wheel geometry that provides for impeller efficiencies up to 78% while reducing noise by up to 3dBA when compared to previous W impellers. B Series impellers feature an all alumnium construction and robot assisted welding.

Aluminium B series plug fans feature a unique seven blade design in which the blade diameter is smaller than the outside diameter of the cover and support plate, allowing it to act as a rotating outlet diffuser. This wheel geometry provides efficiencies up to 78% while reducing noise. Fluid optimised inlet cone made of galvanised sheel metal.

B series impellers offer more air at a higher pressure.

Multiple configurations of motor and electronic combinations are available to achieve improved performance where needed

High efficiency alumnium (AIMg3) impeller.

EC Plug Fans with E Impeller

Optimised for High Flow, Low Pressure

The noise optimised E-Wheel is manufactured from state-of-the-art fibre reinforced plastic (ABS) materials and developed in-house by the Rosenberg Group. E series impellers produce class leading performance in a backward curved offering. Efficiency is optimised using seven profiled blades and a narrow diffuser to maximise static regain through the fan discharge. Ideal for low to medium pressure applications.

Compact, efficient and optimally designed, E series impellers feature a lightweight (1.22kg/m2) black UV stabilised long fibre reinforced polypropylene impeller therefore reducing the mass of inertia and start up resistance to a minimum.

Designed with computer fluid dynamics, the profiled blades and diffuser wheel produces less vibration while significantly reducing noise levels.

E series impellers are geared for maximum performance and efficiency. The optimised inlet conditions reduce the motor interaction with the airflow path, resulting in an increased airflow and pressure.

EC Plug Fans with G Impeller

Optimised for High Pressure

G series plug fans combined with electronically commutated motors form a very compact, efficient and optimised fan unit. The high pressure optimised impeller is manufactured from sheet steel metal coated in quartz grey and features 6 backward curved blades with an efficiency optimised diffuser wheel.

Expertly designed and manufactured to the highest standard, the high pressure optimised G series range of plug fans are available in 3~. A full range of datasheets are available upon request.

The quartz grey (RAL 7039) sheet steel metal impeller of the G series imeller features 6 backward curved, profiled blades and an efficiency optimised diffuser wheel for sound and pressure optimised behaviour.

Ideal for use in sensitive applications including clean rooms, containment and air handling, the Gen 3 motor offer enhances constant volume controllability for reliability and performance.

The G series range impresses with a low depth for simple installation. Fast start up is ensured because of well integrated components. Mounting either horizontally or vertically.

Software Selection

Our customers are invited to download the free fan selections software "RoVent" to compare plug fan performance and efficiencies. Visit Software - Rosenberg Ventilator and click download.

Stock Availability

Our warehouse extension in 2020 means we hold a large volume of plug fan stock for our wide range of OEM customers. If you're looking for plug fans on short lead times, contact us for information on stocked lines.

Integration Expertise

Our expertise lies in fan integration, it's what we've always being good at. So we work with our customers to achieve the best outcome for them, helping them to produce the best air movement systems for their customers.

Plug fans are the work horse of your air handling unit, getting it right is paramount, that's why

We Select the Fan Components that Best Suit your System Requirements

Fans in air handling units contribute a significant impact to energy use and noise. How much of an impact depends on how a fan is selected, installed and operated. Back in 1983, our passionate managing director Grant Edwards, set up Axair in a spare room with a solid goal that still exists today; To provide air movement and fan components that create better systems, systems that help our customers to be more successful. Today our team of committed fan engineers listen to our customers problems attentively, focusing on core of the task you've set out to achieve, and select fan components that do just that, help you to create better systems. Not just the sale that makes our bottom line look better.