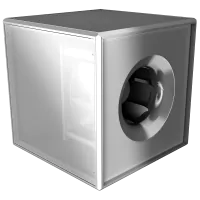

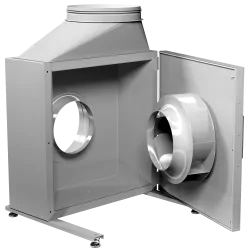

Backward Curved Centrifugal

Popular High Pressure Backward Curved Centrifugal Fans for OEM Applications

Being one of the most popular type of industrial fan for UK OEM's, backward curved centrifugal fans play a vital role in high pressure air movement applications due to their design. European fan manufacturers Rosenberg and Ecofit, a part of the Rosenberg Group deliver constant innovations in backward curved technology to deliver a comprehensive and enviable range to allow our customers to integrate the perfect selection into their finished units.

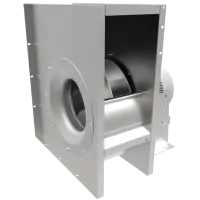

With a wide range of industrial fans featuring backward curved impellers to facilitate their final performance and suitability for niche applications, we advise customers to contact us to discuss your specific application requirements.

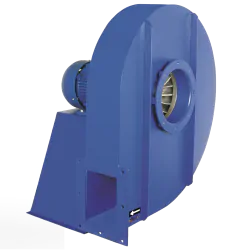

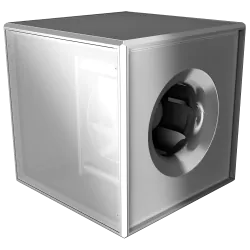

Fans that Offer Long Term Benefits and Efficiency Gains

Although slightly more expensive than forward curved fans, the complex design of the backward curved impeller increase the versatility and performance of the overall system. Manufactured by the Rosenberg Group, our backward curved centrifugal fans balance cost and efficiency perfectly. Talk to us for accurate product specifications.

With an extensive range of motors developed to ensure the optimised performance of our backward curved fans, our team will work with you to ensure the right impeller and motor combination delivers exactly what your system needs.

Learn more about Ecofit motor developments here.

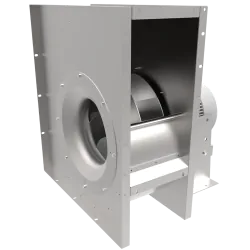

Backward curved impellers are well suited to both clean and dusty environments because of their blade design. The curved blades help to reduce the accumulation of dust and debris on the blades, minimising the risk of degradation of performance and contamination. This makes them ideal for applications that demand clean air circulation.

Common applications where our backward curved fans are used, include AHUs and general HVAC for improved efficiency and higher static pressure capabilities, Cleanrooms where airflow must be controlled and contamination must be minimised, industrial processes such as air pollution control where high airflow and pressure requirements exist, and data centers focusing on efficient cooling and airflow management.