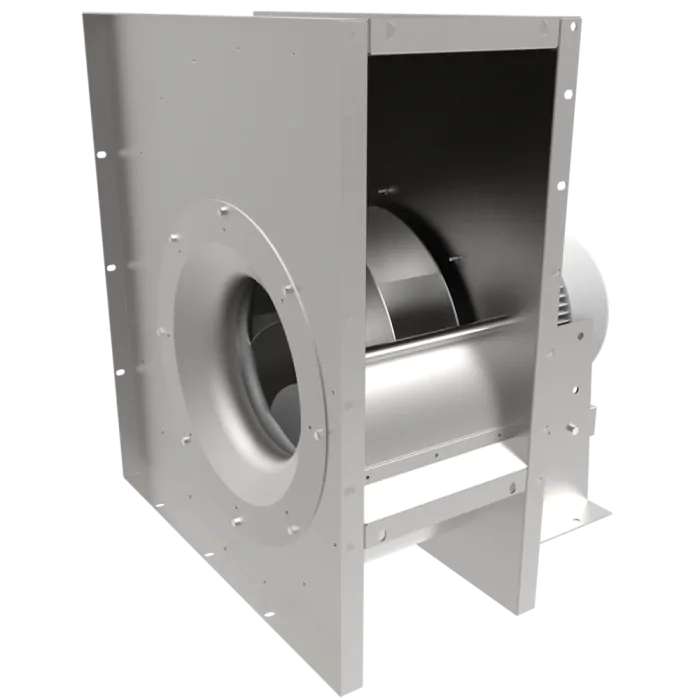

EHND & EHNE Backward Curved Centrifugal Fans

Available in Standard or ATEX Versions

Manufacturing Features:

Centrifugal fan made of galvanised sheet steel

Flow rates up to 21,000 m³/h

Size: 200 - 630 mm (impeller diameter)

Casing position: LG or RD

IEC standard motor, IP55, thermal class F

Backward curved impellers

Terminal box directly on motor, IP55

Motor protection through PTC thermistors

Featuring High Efficiency Impellers

Both the EHND and EHNE series feature backward curved impellers made of aluminium with galvanised sheet steel inlet cones and offer a highly energy efficient solution. All impellers are balanced dynamically and statically in accordance to quality level G 2,5 DIN ISO 1940 on two levels.

EHND: Single inlet backward curved centrifugal impeller, IEC standard motor, three phase

EHNE: Single inlet, backward curved centrifugal impeller, IEC standard motor, single phase

The backward curved impellers are made of aluminium with galvanised sheet steel inlet cones.

All impellers are balanced dynamically and statically in accordance to quality level G 2,5 DIN ISO 1940 on two levels.

IEC motors are characterised by a compact, robust design and are controllable in combination with variable frequency drives. IEC motors are more commonly situated outside of the airstream so can deal with higher temperatures than motors that sit in the airstream (for example, external rotor motors).

The standard temperature of the ventilated air or gas is -20°C up to 60°C. However, if the motor does not directly get in contact with the hot air, the fan has a resistance of up to 100°C. If there is a requirement of the fan to handle air that is up to 120°C, special measurements of the temperature surrounding the motor must be monitored constantly.

To handle colder air than in the standard range, special bearings suited to very low temperatures can be used. This will allow for air handling to a minimum of -40°C.

Typical applications include the ventilation of workshops and industrial buildings.

Axair offer versions of the series that are ATEX certified that can be used in areas deemed to have a risk of explosion such as;

•Fuel stations

•Food processing

Technical Data

The EHND and EHNE series are paired with IEC motors which are characterised by a compact, robust design and are controllable in combination with variable frequency drives. IEC motors are more commonly situated outside of the airstream so can deal with higher temperatures than motors that sit in the airstream. The standard temperature of the ventilated air or gas is -20°C up to 60°C. However, if the motor does not directly get in contact with the hot air, the fan has a resistance of up to 100°C.

| Fan Type | Voltage (V) |

Frequency (Hz) |

Input Power (kW) |

Rated Current (A) |

Speed (rpm) |

Max Temp (°C) |

IP Rating (IP) |

|---|---|---|---|---|---|---|---|

| GKHM 355-CIG.102.5HF IE Gen3 (IE5) | 3~ 380-480 | 50 / 60 | 2.33 | 3.7 at 400V | 3120 | 40 | IP54 |

| GKHM 400-CIG.114.6FF IE Gen3 (IE5) | 3~ 380-480 | 50 / 60 | 4.48 | 7 at 400V | 3170 | 40 | IP54 |

| GKHM 450-CIG.128.6IF IE Gen3 (IE4) | 3~ 380-480 | 50 / 60 | 5.9 | 9.05 at 400V | 2950 | 40 | IP54 |

| GKHM 500-CIG.143.6NA IE Gen3+ (IE4) | 3~ 380-480 | 50 / 60 | 7.48 | 11.4 at 400V | 2625 | 40 | IP54 |

| GKHM 560-CIG.160.6NA IE Gen3+ (IE4) | 3~ 380-480 | 50 / 60 | 6.85 | 10.7 at 400V | 2125 | 40 | IP54 |

| GKHM 630-CIG.180.6NA IE Gen3+ (IE4) | 3~ 380-480 | 50 / 60 | 5.1 | 7.88 at 400V | 1580 | 40 | IP54 |