Commercial Kitchen Extract Fans

Kitchen Extraction Fans that Meet the Demands of Commercial Extraction

Commercial kitchens demand that extraction fans and exhaust fans are made from high quality components to withstand the rigours of continuous contact with hot, greasy air. In such environments, air change is supplied by a mechanical ventilation system. This is usually via an extract canopy situated above the appliances that is exhausted via a roof fan or horizontally through ducting. Sufficient outdoor air must be provided through supply fans to replace the extract air to avoid creating a vacuum. Therefore, a combination of supply air fans and commercial kitchen extractor fans are required. In hotter climates, an air handling unit may be required to cool air before supplying back into the kitchen environment, but in clement environments, standard plate axial fans mounted on a wall would suffice allowing a regular intake of fresh air from atmosphere.

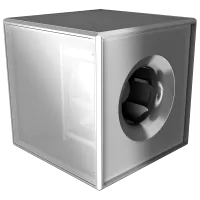

Many of the fans in out kitchen extraction ranges have double skinned galvanised sheet steel casings with a non-flammable rock wool acoustic and moisture insulation. This reduces noise levels and means that the fan can carry hotter air whilst preserving the life of the motor. ATEX versions available on request.

Options for Supply Air & Extraction in Commercial Kitchens

The type of kitchen extraction fan depends on the type of ventilation and extraction system used, however in all systems, sufficient outdoor air must be provided through supply fans to replace the extract air to avoid creating a vacuum. Therefore a combination of supply air fans and commercial kitchen extractor fans are required.

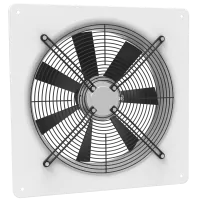

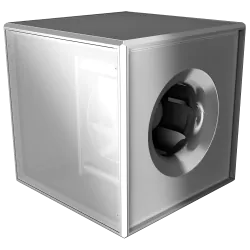

The supply of fresh air can be achieved with a simple cased axial or plate axial. In some circumstances, a centrifugal fan in a box mounting can be used depending on the volume and pressure requirements of the application.

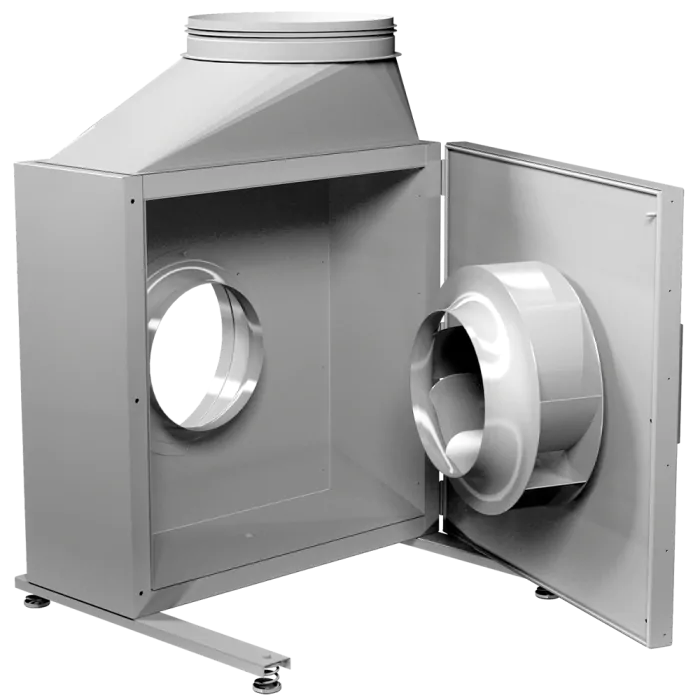

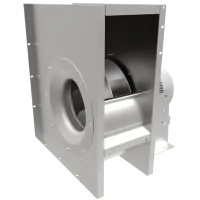

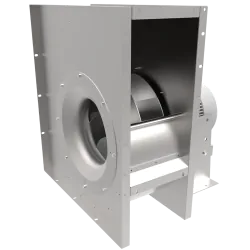

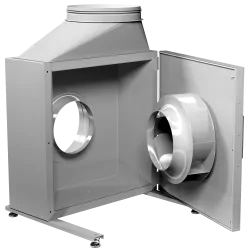

To move the contaminated air out of the extract canopy, there are two common methods. The first is to pull the air through ducting, often containing HEPA filters and carbon filters, horizontally using centrifugal extractor fans specifically designed for use in commercial kitchens.

For example, the KB range from Rosenberg are driven by motors located out of the air-stream, allowing the impeller to operate at temperatures up to 100°, while the housing remains cool due to the manufactured thermally insulated skin. The motorised impeller is built on to a hinged door, which provides fast access to the fan for cleaning.

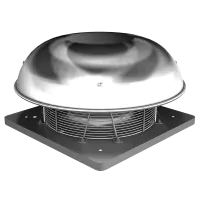

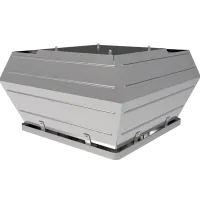

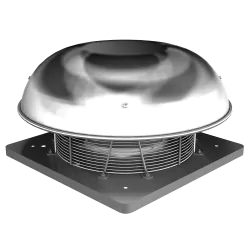

To extract the contaminated air vertically out through the roof of the building. In this case, we recommend the use of roof extraction units specifically designed to dissipate air into the outside environment with the use of centrifugal fans.