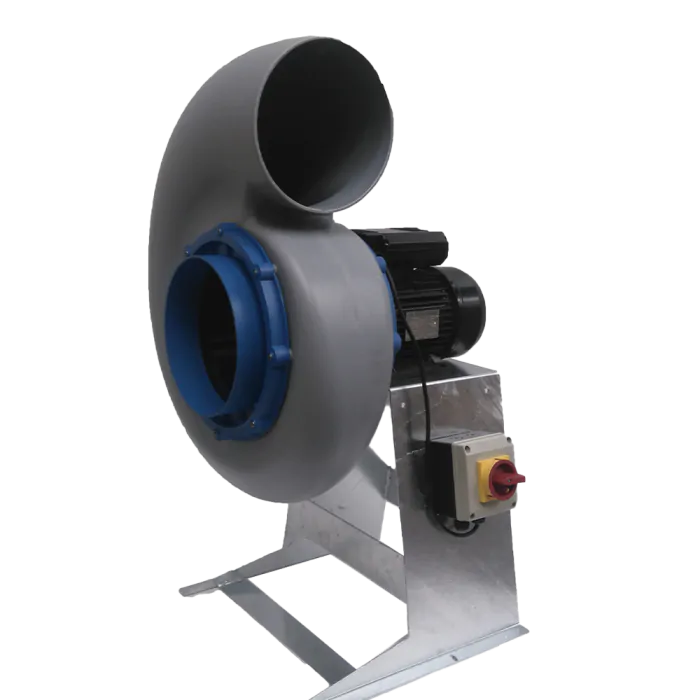

S Range Fume Extraction Fans

Chemically Resistant Polypropylene Fans for Low-Medium Pressure Applications

A high airflow, low pressure polypropylene fan is typically used in fume extraction systems when there is a need to move a large volume of air while overcoming minimal resistance or pressure drops. This includes containment and capture, open duct runs or large fume cupboards where there are no significant obstructions or ductwork restrictions. In other situations outside of extraction, for example where the primary objective is to dilute and remove airborne contaminants rather than capturing them at source, a higher airflow fan can be used. This helps to create air movement and increase the overall air exchange rate within the space to effectively dilute the concentration of contaminants.

On larger fans we may recommend the use of an inverter to obtain a soft start and to avoid overcurrents. The inverter should be set to avoid unnecessary loads on the fan due to high acceleration or deceleration. Contact us to discuss your specification requirements.

Crucial Fan Selections for Safe & Effective Fume Extraction

The selection of an appropriate fume extraction fan is crucial for achieving effective and efficient extraction. One of the most important things we'll ask is for you to consider if you'll ever want to speed control the fan, this will determine if we offer 1~ or 3~ motors. From here, we'll ask what's important and will need additional information, starting with the following:

Accurate assessment of the airflow requirements is essential to ensure proper ventilation and fume extraction. Factors such as the size of the workspace, the volume and nature of the chemical fumes generated, and the fume hood configuration must be considered to determine the required airflow.

The fan should be able to generate sufficient static pressure to overcome resistance from ductwork, filters, and other system components even in the event of clogging, or when soiled. Proper evaluation of the pressure requirements ensures that the fan can maintain the necessary airflow throughout the system.

Chemical compatibility is crucial to avoid corrosion, degradation, or contamination of fan components. The fan materials must be resistant to the chemicals being extracted to ensure durability and long-term performance. Therefore an analysis of the chemicals present is a must.

Consideration should be given to the noise levels produced by the fan. Selecting a fan with low noise emissions is important to maintain a comfortable and productive working environment, as well as contributing to environmental initiatives and BREEAM assessments.

Choosing an energy efficient fan helps to reduce operational costs, lifetime reliability, scope 2 carbon emissions and environmental impact. Fans with high efficiency motors, variable speed drives and intelligent controls can optimise energy consumption based on the actual fume extraction requirements. View the EC range of industrial fume fans here.

Ensure that the selected fan meets relevant industry regulations, standards and guidelines for workplace air quality and fume extraction. Compliance with regulations ensures a safe working environment and avoids regulatory issues. This includes both ATEX UK & EU directives.

An important consideration before starting to choose a fume extraction fan is whether or not the system will need to change in the future. If additional duct runs are added this may mean that the fan should be able to deal with an increase in system duties and therefore a larger fan should be selected.

SEAT Corrosion Resistant Fans

High Airflow Polypropylene Fume Fans

Designed to exhaust and resist fumes from highly corrosive environments such as laboratory fume cupboards, battery rooms, chemical plants, etc. The UV treated polypropylene construction and thick walls ensure maximum protection against acids and corrosion. 50-15000 m3/H and 10-1800Pa of total pressure.

Available in 6 sizes:

S15, S20, S25, S30, S35 & S50

All sizes are available as ATEX certified

EC available in S15, S20, S25, S30 & S35

Handings and orientations matter for fume extraction fans as they directly impact the airflow direction of the fan within the system or minimise the bends in system design. Incorrect handing or orientation can result in inefficient airflow patterns and poorly captured fumes. Incorrect choices can also affect noise and vibrations levels generated by the fan.

You should advise your fan supplier of the required fan handing and orientation at the point of order. A project can be stalled or delayed as fan suppliers will not process an order without this information. This ensures the product performs as required in your system.

Depending on the desired airflow pattern and the specific requirements of the extraction system, the impeller rotation can be set to LG (Right rotation) or RD (Left rotation). Multiple discharge positions are available but it is important to ensure that the right handing is chosen before installation. We do not advise that any contractors change the handing themselves, this can lead to the system only achieving 30% of the duty.

We assist specifiers, OEM's and contractors to integrate our corrosion resistant fans into their designs by supplying BIM, CAD and STEP files for all of our products.

Contact our team with the fan reference so that we can issue you with the correct file.

ATEX Environments

Available for Zone 2 Hazardous Atmospheres

In applications involving the extraction of chemical fumes in hazardous environments it is essential to select fans that comply with the ATEX regulation. ATEX polypropylene fans are specifically designed and certified to operate safely in potentially explosive atmospheres.

These fans incorporate features such as explosion proof motors, spark resistant construction materials in permissible pairings and their design characteristics incorporate maximum surface temperature limitations to minimise the risk of ignition through the auto ignition of flammable gases. When evaluating ATEX fans for a fume extraction system, ensure they are certified for a specific hazardous zone.

Consult with experts in ATEX compliance who will carry out a hazardous area classification to determine the presence of explosive dusts or gases.

ATEX polypropylene fans are carbon loaded to reduce static discharge in hazardous environments. Carbon loading is a process in which carbon particles or fibres are incorporated into the polypropylene material during manufacturing. The addition of carbon to polypropylene enhances conductivity allowing it to dissipate accumulated static charge more effectively, minimising the risk of electrostatic discharge (ESD).

Static discharge can be a concern in certain environments where flammable or explosive substances are present. Where airflow passes through the fan blades, friction can generate static charges on the fan surfaces. In environments with potentially combustible materials, static charges can potentially ignite or trigger an explosion.

Complete Fume Fan Pack

A Fume Fan Kit Ideal for Educational Fume Fan Replacements

A complete custom configured fue fan pack containing all of the necessary components to simplify the installaton of laboratory fume fans in school and university fume extraction system retrofits.

The fan pack offers a more cost effective solution than sourcing components seperately, and reduces installation time and costs for installers and contractors.

The fume fan in your pack will be selected to match the operating duty of the fume cupboard you'll be fitting the fan.

We will customise your pack by discussing the available space, current set up, mounting optons, and operating and duty points of your fume cupboard to determine the exact contents you need.

This includes:

•Polypropylene fan•Isolator

•230V 1~ motor. EC available

•230/400V 3~ direct-on-line or inverter supplied

motor. EC available

•400/690V 3~ motors in larger sizes

•Pre-wired electrical isolators

•Motor starters

•Inverter drives

•Airflow controllers

•ATEX motors

•Multiple handing options

•Metal or weather proof box pedestal

•Anti-vibration mountings

•Flexible connectors

•Flange pairs

•Manual dampers

•Drain hose connectors

•ATEX polypropylene/carbon fans

Our customers benefit from short lead times and unrivalled stock availability on an extensive range of fume fans. We‘re confident that our stock and logistics policy enables us to maintain a position that will provide continuity of business and a cost effective solution to industrial corrosion resistant fan procurement.

Stock Availability

All of our polypropylene range of fans designed especially for use in industrial fume extraction are stocked in our Staffordshire warehouse for immediate build and despatch.

We Select the Fan Components that Best Suit your System Requirements

At Axair Fans we have a simple goal: to provide air movement and fan components that create better systems, systems that help our customers to be more successful. Today our team of committed fan engineers listen to our customers problems attentively, focusing on core of the task you've set out to achieve, and select fan components that do just that, help you to create better fume extraction systems. Not just the sale that makes our bottom line look better.