ATEX Concepts: Understanding Temperature Classes & Maximum Surface Temperature

In many industrialised countries, during manufacturing, treatment, transport and in the storage of goods, gases, vapours or mists are produced or leaked into the environment. Flammable dust can also be produced which in combination with the oxygen in the air can create a potentially explosive atmosphere that can coupled with a source of ignition create an explosion. There are many sources of ignition, some can happen as a result of electronic failure, mechanical failure, or the friction of an impeller with the inlet causing static discharges.

The Creation of an Explosive Atmosphere

Before we move on to temperature, let's discuss some basics about explosive atmospheres. An explosive atmosphere is defined as a mixture in atmospheric conditions caused by the activity of manipulating of the air and flammable substances (gas, vapour or dust). These explosive atmospheres can occur in many industrial activities that surround us such as the chemical industry, power plants, landfills, food processing factories and metallurgical industries.

There are two types of ATEX atmosphere:

1 - Explosive Gas Atmosphere Mixture of the flammable substance with the air. Combustion is spread to the entire unburned mixture on ignition.

2 - Explosive Dust Atmosphere Mixture of the air with flammable substances in the form of dust or fibres. On ignition the combustion propagates through the rest of the unburned mixture.

Depending on the duration and presence of an explosive gas or dust in when the fan is in operation, zones and categories are determined for an explosive environment. This dictates the level of explosive protection components must have in order to be placed in those atmospheres. Explore gas and dust zones here.

Maximum Surface Temperature

According to the BS EN 14986 standard, both the temperature of potentially hot surfaces and the temperature of the conveyed atmosphere (flammable or not) and/or of the atmosphere surrounding the fan shall be considered when determining whether a component is suitable to place in a hazardous area. The maximum surface temperature of the fan characterises the hottest part of the equipment that can come in to contact with the explosive atmosphere or the maximum temperature of the conveyed atmosphere (flammable or not) which can act as an ignition source. If the temperature on the surface of the motor exceeds this level, ignition of either the gas or dust is possible. This is a required indication that the customer should communicate before selecting an industrial fan for use in an explosive atmosphere. Hot surfaces become dangerous around 135 degrees Celsius so for that reason all ATEX equipment should be selected as having a T class of T4, T5 or T6. Generally, we'll work with a safety margin of around 20% between the ignition temperature of the gas present, and the equipment nameplate rating to ensure you're covered with the industrial fan that is selected. This is the reason the T class must be given when enquiring for an ATEX fan. For dust, two different ignition temperatures need to be controlled: the ignition temperature of a dust cloud, and that of a dust layer to 5mm. The maximum surface temperatures of both the inside and outside parts of the fan that can come in contact with the explosive atmosphere shall be determined in accordance with EN ISO 80079-36. In addition to that, the maximum surface temperature marked for the inside of the fan shall be the greater of either: — the maximum surface temperature determined in accordance with EN ISO 80079-36 including the appropriate safety margins for the different categories, or — the maximum temperature of the conveyed atmosphere (flammable or not) at the outlet with a safety margin of 20 % (with temperatures measured in °C).

Example of Temperature Class Marking

A fan with the following parameters: The maximum surface temperature of the inside, measured according to EN ISO 80079-36 with the appropriate safety margin is 90 °C, the temperature of the conveyed atmosphere (flammable or not) measured at the outlet is 80 °C for an inlet temperature of 60 °C. With a 20 % safety margin the maximum outlet temperature is 96 °C. Therefore, the maximum temperature marked for the inside of the fan is 96 °C.

Temp Class of the Max Surface Temp Must Be Defined So That Dust: Maximum surface temperature shall be equal or lower than the lowest value of:

- Temperature limit 1 = 2/3 of the minimum ignition temperature for the existing dust cloud.

- Temperature limit 2 = Minimum ignition temperature for a 0.19 inches powder layer less 75 Kelvin.

- Ignition temperature of a dust layer -75 degrees °C

For dust, the maximum surface temperature should be used as an absolute figure, not a temperature class.

The lowest limit temperature in both cases has to be higher than the maximum temperature on the devices surface. For example in the case of wheat flour:

- Temp limit 1 = 2/3 x 480 = 320° C

- Temp limit 2 = 450 - 75 = 375°C Maximum temperature of devices surface = 320°C

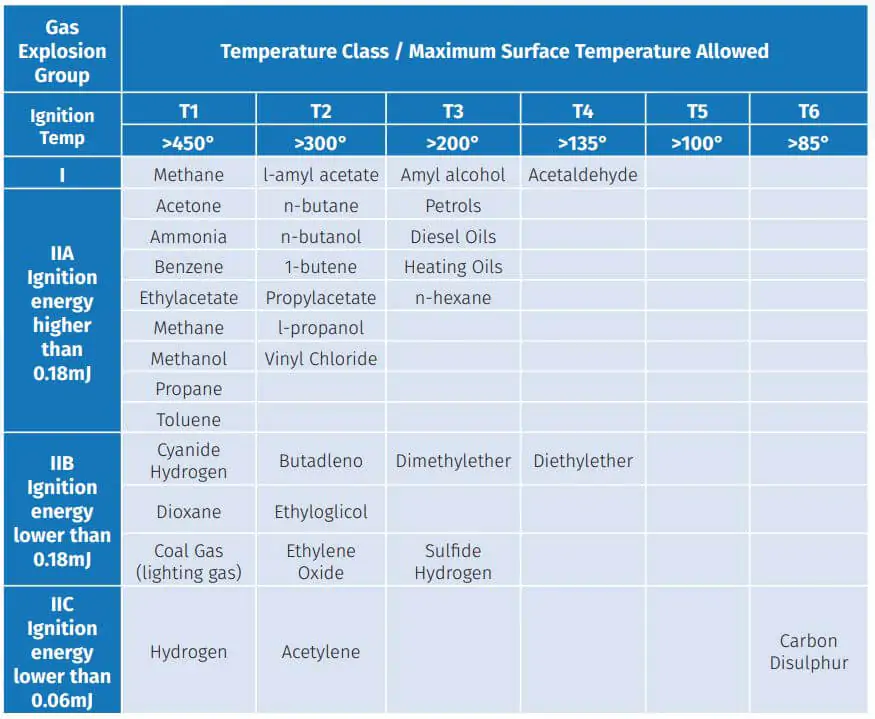

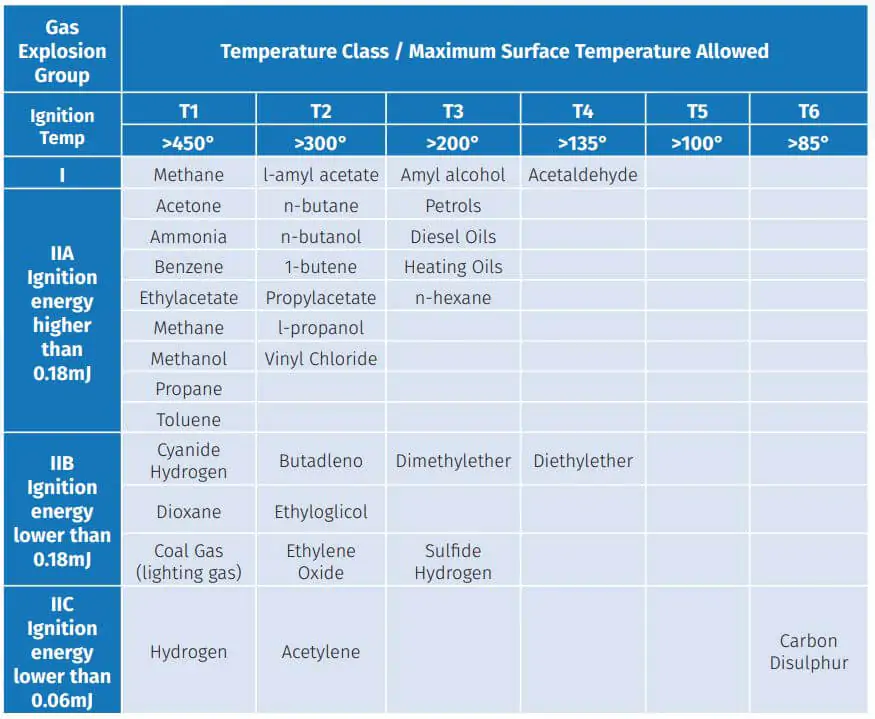

According to the below table, the wheat flour example temperature class is T2.

Lower explosion limit (LEL) is in this case 125g/m3. Below this concentration there's no explosion risk. See the table below for indicative ignition temperatures and ATEX temperature classes for gases:

When sending information to our technical fan engineers the user must advise the temperature class for gases or the surface temperature for dust according to the type of substance present in the air that will be present in or around the fan. The user should also advise of any incompatibilities between materials used for ATEX fan constructions such as copper or aluminium alloys, and the gases in the airstream. View more information about IIC Hydrogen exhaust here or learn more about ATEX gas and dust zones in our technical section.