EC Industrial Fume Extraction Fans

EC Fume Fans to Extract & Resist Corrosive Fumes in Laboratory Extraction

As the market demands more energy efficient fume extraction systems, the EC range of polypropylene fume fans allow fume extraction fan designers, specification consultants and fume cupboard manufacturers to reduce their system energy consumption significantly without affecting performance. Ultimately enhancing the energy efficiency of the entire fume extraction system.

The IP55 polypropylene range of EC fans and motors are available in a variety of sizes in both single and three phase variants covering airflows from 20-9000m3/hr and pressures to 1500Pa.

Contact our in-house team of industrial fume experts to help with EC product selections.

Reduce Scope 2 Emissions & Energy Consumption by up to 20% Without Affecting Performance

Scope 2 carbon emissions relate predominantly to the building and its infrastructure, the daily business activities, and the operational processes of the building. The energy efficiency of these activities, processes and equipment has a large impact on the potential to reduce scope 2 carbon emissions. Scope 2 refers to activities where energy is purchased, and consumed, for example in running fans and motors in HVAC, fume extraction systems, or laboratory activities.

Much of the operational energy use within laboratories is associated with the high rates of ventilation required to maintain air quality in air handling units, or to maintain face velocity in individual, manifold or local exhaust fume extraction systems.

Many UK companies are working in accordance with the greenhouse gas protocol (GHG) and recording their scope 2 carbon emissions. A 20% reduction in energy consumption has a significant impact on a helping a business to acheive its future net zero goals by reducing carbon emissions.

Electric motors account for approximately 45% of all global electricity usage and 75% of all industrial electricity usage. Efficiency is especially important in today’s climate, for reducing CO2 emissions but also for reducing the cost of the motor over its lifecycle.

BREEAM, which stands for “Building Research Establishment Environmental Assessment Method” is a voluntary building certification scheme that many UK local authorities, new buildings, and universities have incorporated into their planning process as a mandatory requirement for sustainable building management. It is used to measure the environmental performance of new and existing buildings, and is now considered best practice in acheiving sustainability. BREEAM awards credits for different environmental features which are combined to achieve an overall score. BREEAM compliant buildings are certified on a five-point scale of pass, good, very good, excellent and outstanding.

High BREEAM ratings for refurbishments in research or laboratory settings are complicated but are required to achieve sustainability goals. Educational laboratories are one of the largest energy consuming sectors in the UK, consuming between four to six times more energy per square metre than standard offices or commercial buildings.

Under the BREEAM assessed category energy, Ene.07 focuses specifically on energy efficient laboratories. For suitable laboratories, up to 4 credits are available for best practice energy efficient measures. The energy efficiency measures implemented must result in a reduction in the total energy consumption of the laboratory of at least 2% to be considered effective.

Learn more about sustainable laboratory ventilation here.

Chemically Resistant Polypropylene

UV Treated, Long Lasting Single Inlet Forward Curved Fans

Fume extraction system designers are increasingly keen to look at all options to reduce energy consumption within laboratories, therefore the addition of the EC range of fume extraction fans is a popular choice to meet sustainability goals without affecting system performance.

6 core sizes of energy efficient fume extraction fan with 1~ or 3~ IE5 ultra premium efficiency motors.

•Single inlet corrosion resistant UV treated polypropylene scrolls

•Forward curved impeller in polypropylene

•Direct drive polypropylene turbine that is balanced dynamically and electronically

•Available in 2 directions of rotation according to the positioning of the suction and discharge (LG/RD)* Except SEC35 in LG only

•Max temp of air carried: -20 – +70 degrees Celsius

•1~ or 3~ B34 type motor: Foot mounted + inner flange

•Integrated Drive on 1~, Inverter Drive on 3~

•High Efficiency EC technology IE5 motor with integrated electronics

•Up to 20% savings on the previous motor type

•IP55 Protection

•Motor positioned out of the airflow

•Drive will control the motor via a 0/10V signal

•Working Temp: -20 – +60 degrees Celsius

•IP66 frequency inverter for EC motors with 0/10V output, an RJ45 relay and alarm contact

Mounting on two pedestal options:

•Metal pedestal

•Outdoor weatherproof pedestal

Chemical resistant fans are manufactured from polypropylene. Polypropylene is a semicrystalline polymer meaning its molecular structure, otherwise referred to as its crystallinity, is very compact and in order. The structure remains solid up to a moderate temperature, resulting in a strong and durable material that has a high resistance to many aggressive chemicals. The resistance to chemicals can vary at different concentrations and with rising temperatures. At room temperature, polypropylene is resistant to most organic solvents, fats and many nonoxidising acids and bases. However, in temperatures rising above 60°, its chemical resistance to certain substances can decrease.

It is important to consider which type of material is best suited to a corrosive application. Stainless steel fans with a marine grade finish have added corrosion protection and could be a more suitable option in applications that utilise oxidising chemicals especially as strong oxidising chemicals may cause damage to polypropylene. By talking to a specialist fan supplier, they will consider environmental factors to determine the material type that offers the most suitable characteristics.

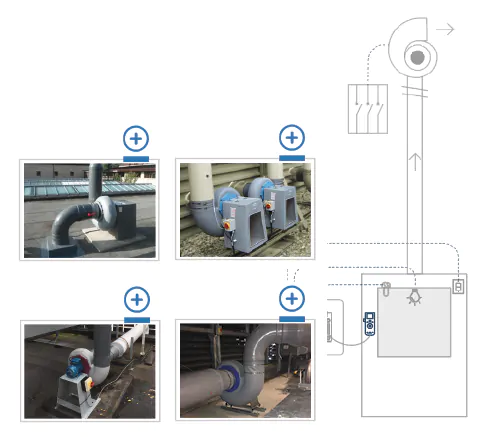

Build Highly Efficient Fume Cupboards

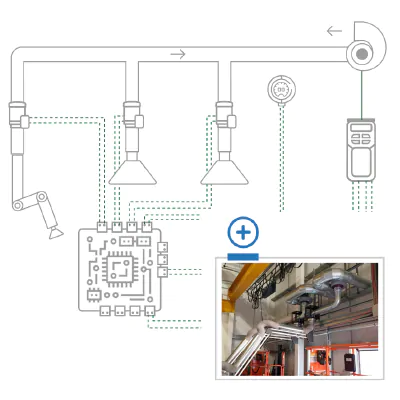

EC Fume Extraction Fans to Increase Overall System Efficiency

An efficient exhaust fan is key to providing an effective fume cupboard that protects laboratory workers and technicians from exposure to toxic chemicals.

Our IP55 polypropylene range of EC fans and motors are available in a variety of sizes in both single and three phase variants covering airflows from 20-9000m3/hr and pressures to 1500Pa. Where laboratories use an individual or manifold fume extraction system, whether recirculating with a fan installed in the cupboard, or exhausted into atmosphere, efficiency should be a part of the selection process for the manufacturer of these units. This means balancing energy consumption with overall fan performance to ensure that the fume cupboard performs as expected in all conditions. Our team can ensure a fan is selected that can perform as required.

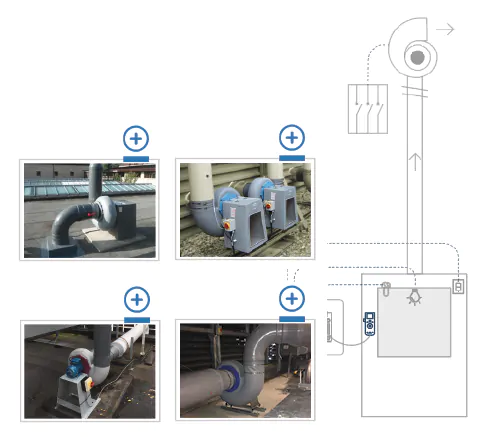

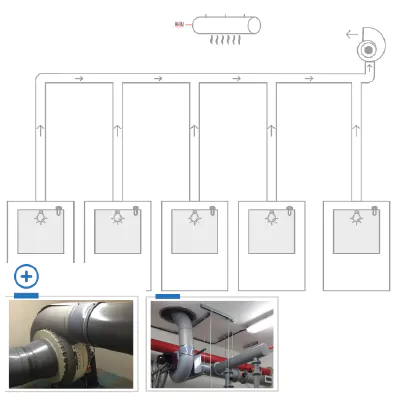

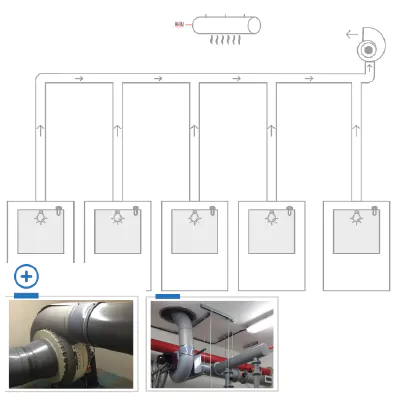

Improve Energy Consumption in Manifold Systems

Powerful EC Fume Extraction Fans for Demanding Manifold Systems

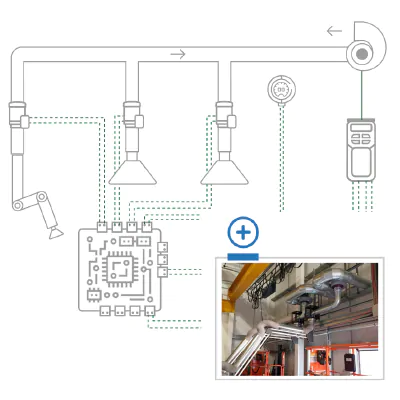

Manifold extraction systems are designed to extract fumes from multiple sources and channel them through a centralised ductwork system. These systems are commonly used in industrial and lab settings where there are multiple workstations or processes generating chemical fumes or hazardous substances.

The layout and design of the ductwork system play a significant role in determining the fan size used in a manifold system. The length, diameter, and complexity of the ductwork, as well as the number of bends, elbows and transitions can create resistance to airflow. The fan must have enough capacity to overcome the resistance and maintain the required airflow rate throughout the system.

Reduce Extract Costs in LEV Systems

High Resistance to Acidic Fumes, Alkalis Corrosive Gases and Other Chemicals

When selecting corrosion resistant fans for local exhaust ventilation systems that require chemical resistance, it is important to consider the specific corrosive agents present in the environment. Corrosion resistant fan selection ensures longevity and performance of the fan in the presence of corrosive substances. Therefore you should identify the specific gases that the LEV system will be exposed to.

We're resourceful and solution led to your needs, therefore we

Focus on Finding the Right Fume Fan to Help You to Build Better Extraction Systems

Where laboratories use an individual or manifold fume extraction system, whether recirculating with a fan installed in the cupboard, or exhausted into atmosphere, efficiency should be a part of the selection process for the manufacturer of these units. This means balancing energy consumption with overall fan performance to ensure that the fume cupboard performs as expected in all conditions. The core of our existance as a business centres around providing fans and fan components that build better systems, systems that help our customers to be more successful. Contact our industrial team who will help you to design, specify or procure the right fume fan to suit your project objectives.

UK Stocked Polypropylene Fans

All of our polypropylene fans are stocked in our Staffordshire, UK warehouse, even the largest one in our range. Therefore, if you need it quickly, we have your back.

Custom Mechanical Fan Configurations

Our warehouse extension in 2020 meant we could hold large amounts of plug fan stock for our wide range of OEM customers. If you’re looking for fans, please contact us to discuss current lead times.

Custom Electrical Fan Configurations

Our expertise lies in fan integration, it’s what we’ve always being good at. So we work with our customers to help them in designing the best air movement system using the resources available.