Air Handling Unit Retrofits

We offer expert advice and fan integration support for OEM's with high quality

Air Handling Unit Retrofits with EC Plug Fan Arrays

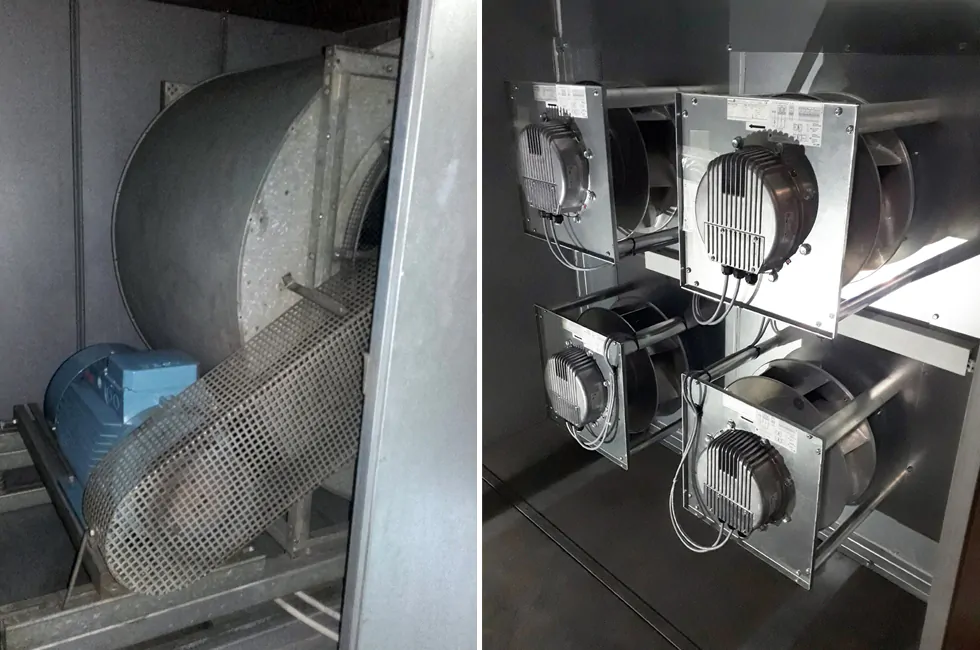

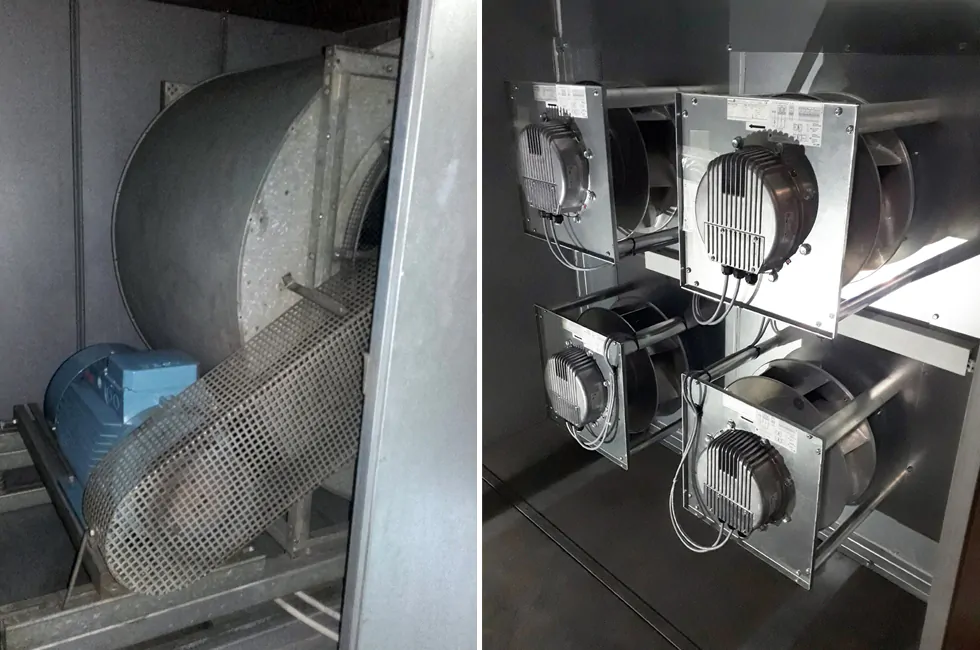

Continuous and consistent airflow is essential to virtually every ventilation unit within buildings or retail units, making under-performing or unreliable belt driven centrifugal fans simply unacceptable. In addition to obvious reliability concerns, these inefficient old style fans can be a building’s biggest energy consumer. Given today’s economy and the increasing cause for environmental concern, HVAC designers select plug fans which will not only provide the necessary reliability, but also provide optimum efficiency and environmental benefits. EC plug fans and the refurbishment of existing air handling units with singular plug fans, or fans laid in a multiple fan array configuration, are the most popular choice for new and existing air handling units following a steep decline in belt driven fan use.

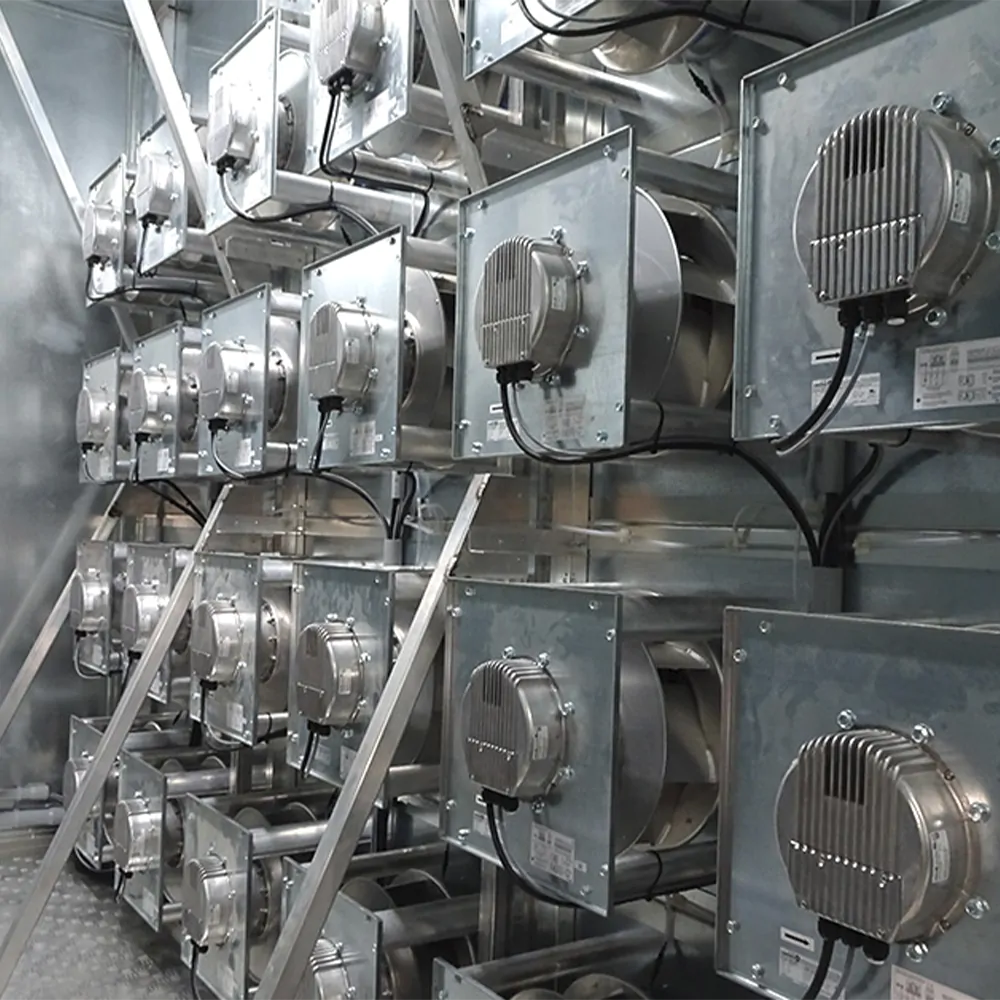

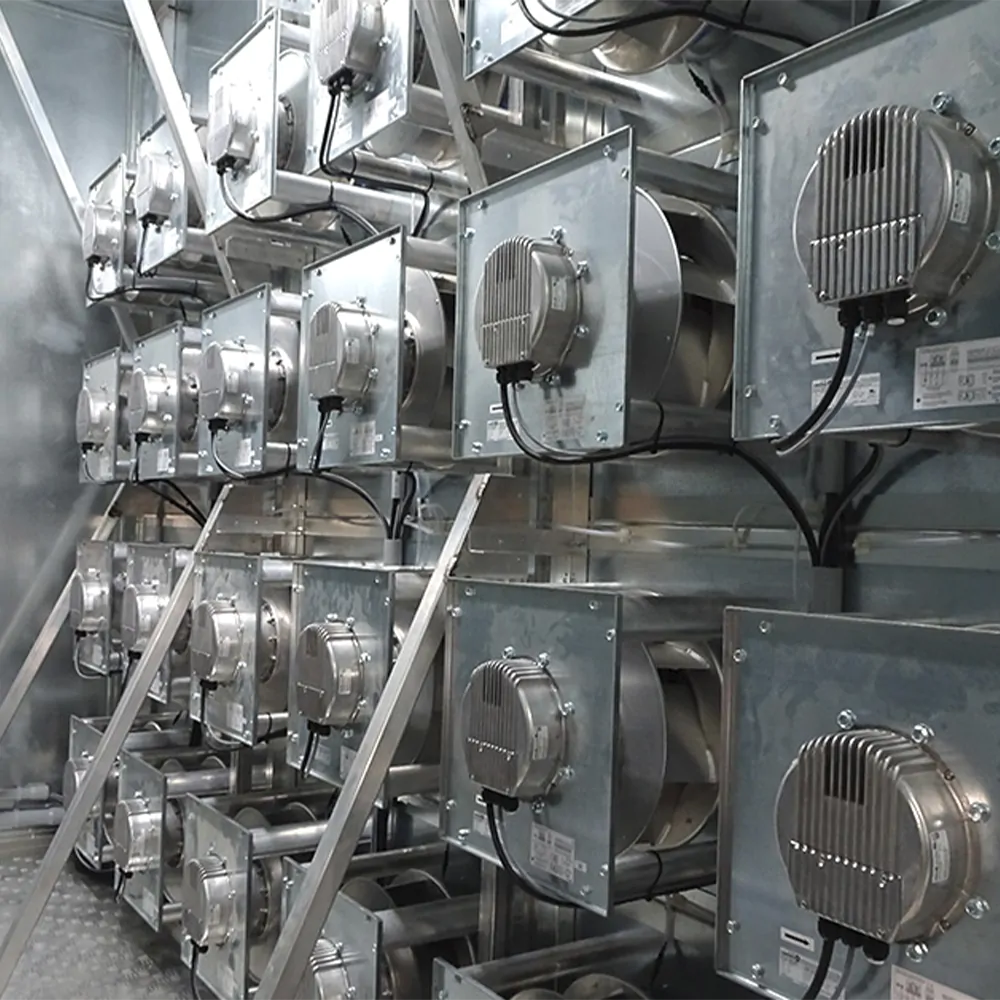

EC FanGrid components are easy to transport, carry by hand by no more than two people, and quick to install. FanGrid kits are delivered in component form as shown above, with guidance instructions on correct and simple build. Installation can be carried out by yourself, a chosen contractor or by our inhouse EC FanGrid installation team in a short space of time with very little downtime. We’ll even handle the hygiene cleans, the removal and book cranes or lifts if required to remove the old system. Please ask for more information.

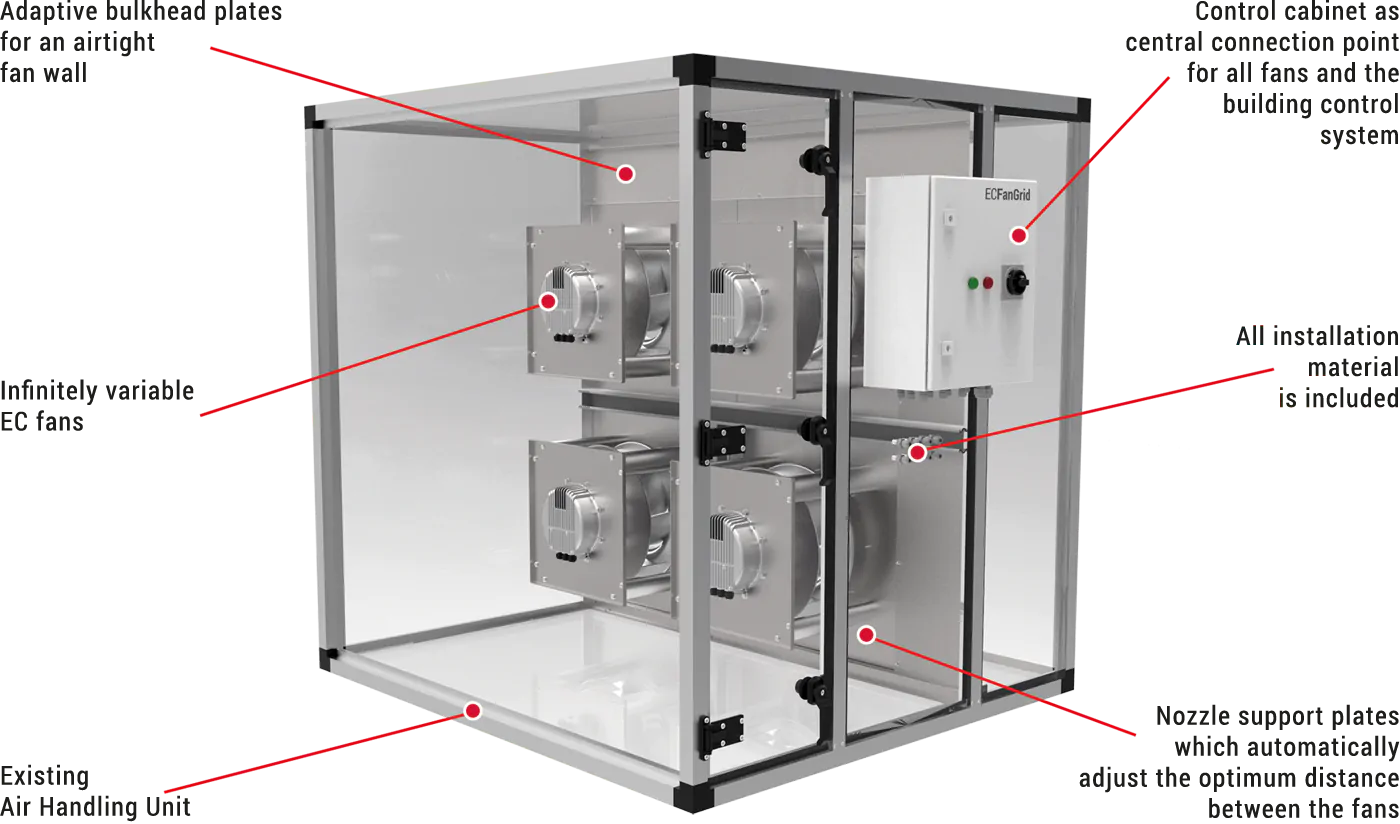

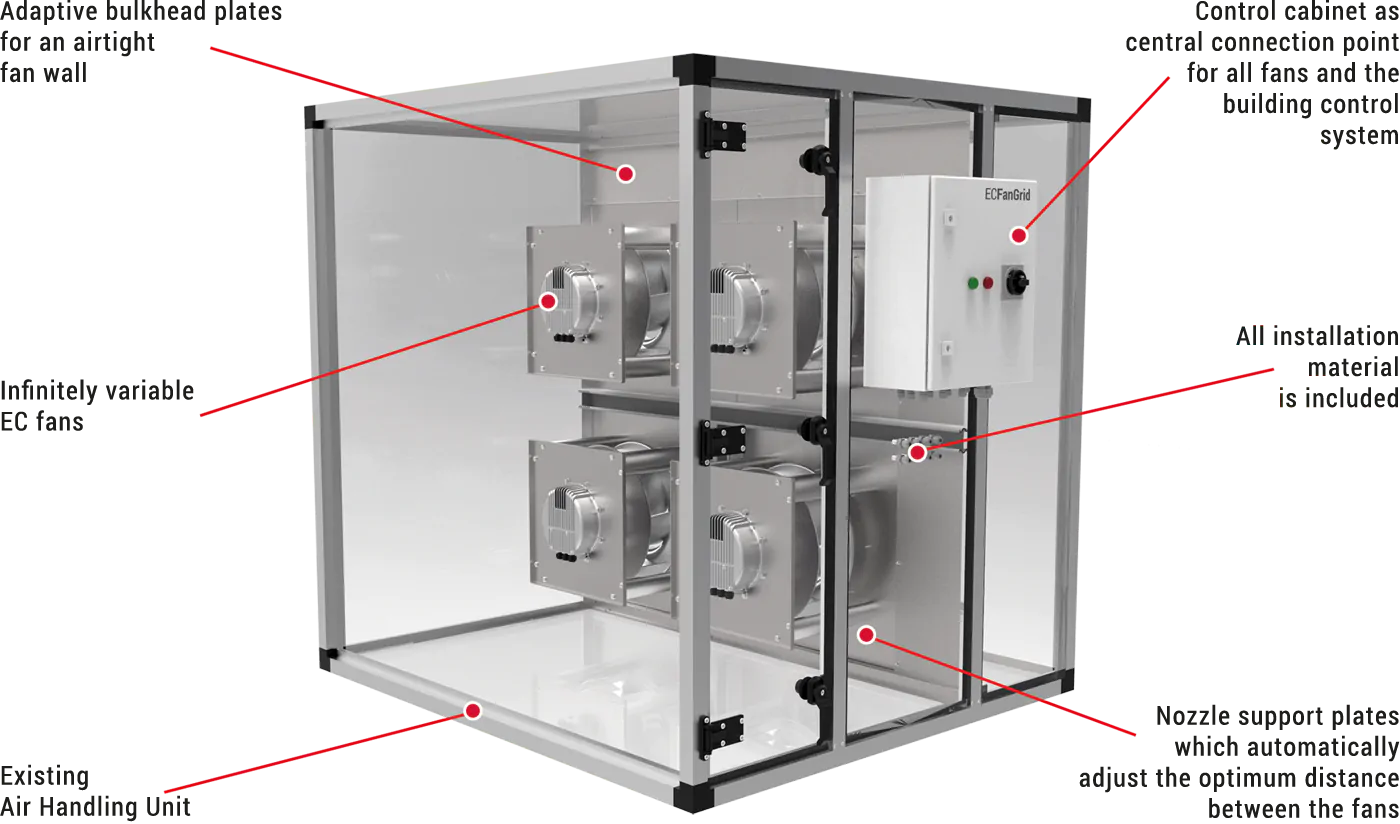

An ECFanGrid consists of several (as many as is required to achieve your system duty, don’t worry we’ll calculate that for you) EC fans operated in parallel in a kind of fan wall. When running multiple fans, the volume flow is multiplied proportionally to the number of fans, while the pressure conditions remain constant. The EC fans used, are not only highly efficient, but as a perfectly matched unit (electronics, motor & impeller) they also enable simple plug & play solutions for almost any ventilation requirement. With BMS and Modbus connectivity they also quickly sync into your building controls.

In addition, several controllable fans can be adapted much better to the actual air performance required, which increases efficiency at every operating point. The ECFanGrid Retrofit System is particularly suitable for replacing old, inefficient belt-driven fans in ventilation units.. The Retrofit System is flexible and always suitable!

All components, from the fans to the switch cabinet and the adaptive sheet metal parts are part of every ECFanGrid Retrofit System from Rosenberg.

In some instances, it is advantageous to use more than one ahu fan in a multiple fan array configuration, for example when it is necessary for the required operating range of the system to include multiple plug fans running closer to their peak efficiencies, instead of one large fan controlled over a wide operating range. Multiple fans for capacity control may be more economical if the cost of operation is critical. By running fans in parallel, when one motor fails, only a portion of the airflow is lots, unlike single fan air handlers.

FanGrids or Fall Walls as they’re commonly known in the industry, provide superior reliability as a result of their built-in redundancy. If one fan fails, only that portion of the airflow is lost, unlike single fan systems where the entire air handler goes offline. Moreover, the loss of airflow from one plug fan can be offset by increasing the speed of the remaining fans.

“Up-grading or retrofitting the fan section in an AHU requires the replacement or removal of a large radial fan, this is typically a costly project due to the construction of the building and the air handling unit. Often the building has grown around the fan unit within the years of operation. There are two options; remove and install a new fan system that can be retrofitted in place of the old one without damage to the building, OR a complete replacement, which can offer extensive opportunities to increase efficiency. Whatever you need, whether supply of fans only, or for us to complete the entire removal and install, we’re here to support you when you need us.”

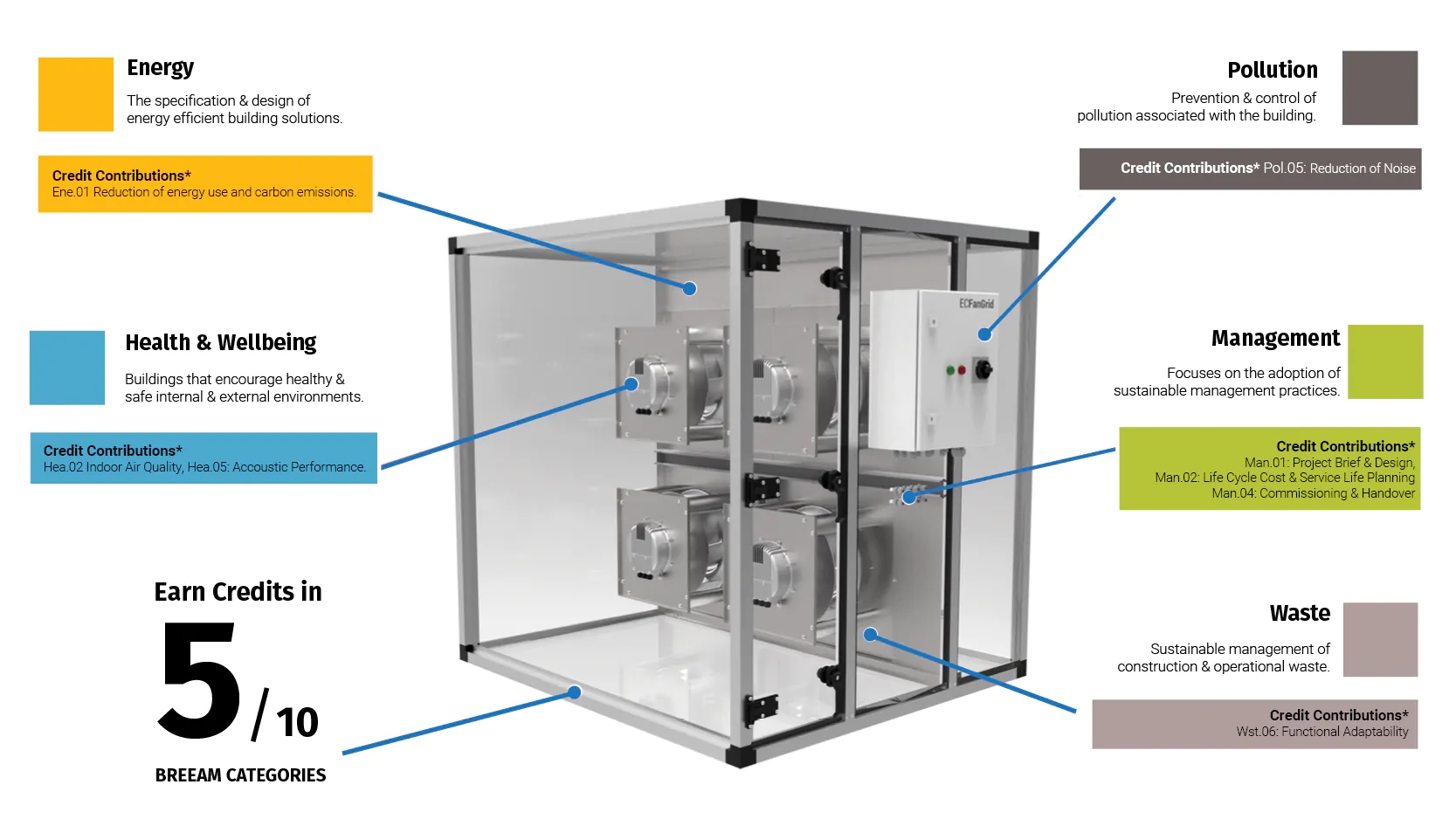

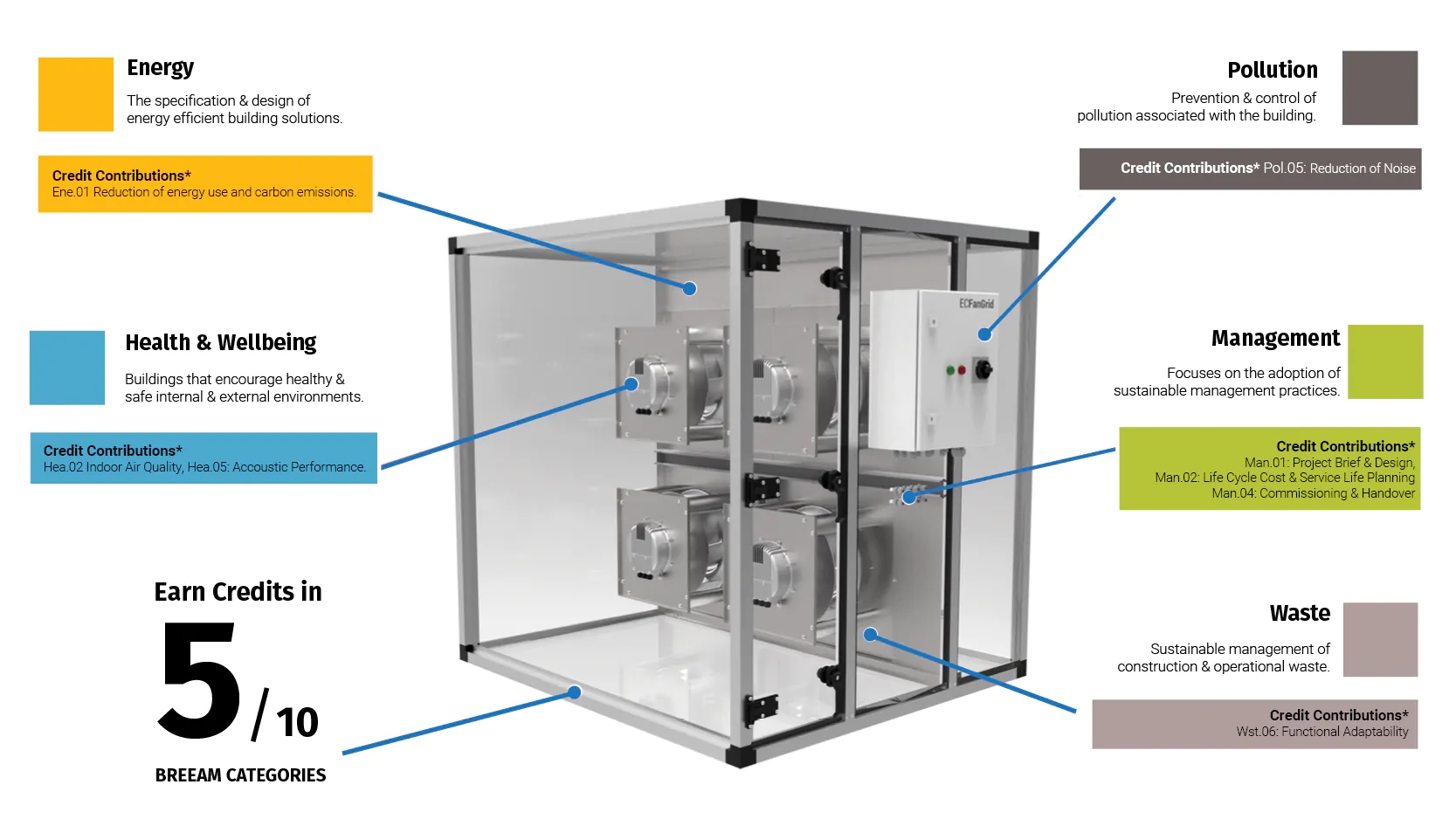

Reducing Scope 2 Emissions with BREEAM Credit Worthy EC Plug Fans for Air Handling Units

Outdated building ventilation systems consume electrical energy at an alarming rate. BREEAM worthy fans for air handling units make a significant contribution to healthy, efficient, carbon and cost-saving green buildings. BREEAM compliance is a UK recognised symbol of sustainability achievement, and is backed by an entire industry of committed organisations and individuals paving the way for market transformation.

HVAC Efficiency with EC Fans

Typically 40% of a commercial buildings energy use comes from heating, ventilating and cooling (HVAV) with 50% of the HVAC energy consumption coming from fans. The move from AC to EC fans in new projects, has been quite significant due to their numerous advantages over their AC comparisons. So, why are EC fans more efficient? EC fans do not need to be inverter controlled due to their built in electronics, can operate outside of their preferred operating range and still maintain a high efficiency, have reduced noise operation when speed controlled and the integrated motor makes for a compact design. Our EC fans have built in control and monitoring capabilities, enabling users to set alarms for fan failures before the system becomes inefficient. Savings as a result of moving from AC to EC occur from both improved motor efficiency and optimising system design.

Considerations & Challenges of AHU Retrofit Installations

Refurbishing an AHU’s costs on average 30% less than installing new units and can add 15+ years to the life of existing air handling units. When replacing old and outdated units, engineers need to consider a number of factors, including the size of the entryways in the building, the spaces used for mechanical and other equipment, and future accessibility of the system for maintenance and repairs. This task can be made more challenging by the location of the units within the air handling system and the physical size of the units being replaced. One old belt driven fan may be physically too large to remove from the building through standard doorways requiring a crane to lift it from the top, or completely dismantled to ensure a complete removal. We’ll help you sort all of this to save you the time and hassle.

The use of AHU specified plug fans and FanGrids in situations where time and space is an issue, risks the least amount of downtime and offers the best opportunity for a rapid return to normal system operation. All components, including the fans are small in size and easy to transport, a huge factor in maintaining a tight replacement schedule and a reduction in costs when compared to alternative solutions.

Read more about the benefits and applications of the ECFanGrid.

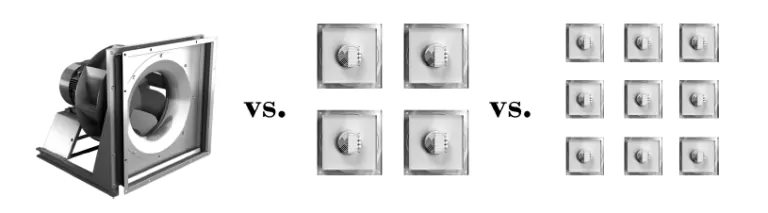

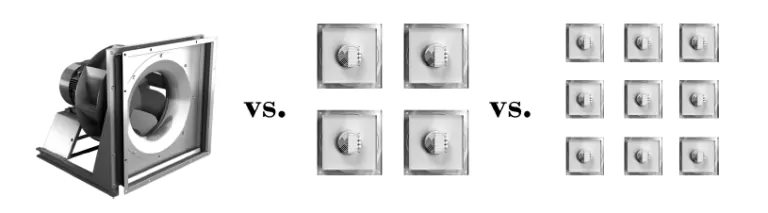

Multiple Fan Array Configurations

The above picture is an example of the flexibility of EC plug fans when used in air handling ventilation systems. A smaller mounting configuration using fans on a plenum and traditional AC inverter controlled motors are still suitable where cost and lead times are the main consideration. Many specifications still ask for standard inverter driven motors in ventilation projects. the centre image shows a 2×2 configuration, while image three shows how this can be scaled up to a 3×3 configuration, simply by adding additional fans into the fabrication.

The number of plug fans in each FanGrid system obviously varies according to the airflow requirements, for example, some may use a wall of nine fans in a three by three configuration. If only eight fans are required for normal operations, the ninth fan will be blanked off with a plate. This can easily be removed if one of the existing fan fails to achieve the duty or the existing fans ramp up accordingly. It’s clear to see from industry changes and company exhibitions such as ISH and EMEX, that the FanGrid is the way forward with air handling unit refurbishments and other HVAC projects. The flexibility, operation and maintenance efficiency and excellent track record for maintaining specific air quality and acoustic conditions, FanGrids are a useful solution. As the technology and sophistication of systems continue to innovate, FanGrids should be considered as a solution for retrofitting old fans as well as new constructions.

If the fan is the work horse of any air handling system then why not work with a fan integration specialist who can survey the existing site, schedule hygiene cleans, remove the existing system, select the right fans for your duty and complete the AHU retrofit. Reduce downtime, improve communication and achieve the best airflow and efficiency as the best fan is suited to your system requirements. Contact us using the form and we’ll get right back to you.

Do you have an old belt driven and outdated ventilation system? Tell us all about it and we'll talk you through the whole process to determine if a multiple fan array is right for your air handling refurbishment.