ECFanGrid Multiple Fan Array Systems

Improve reliability, flexibility and efficiency in air handling unit retrofits with our

ECFanGrid Multiple Fan Array

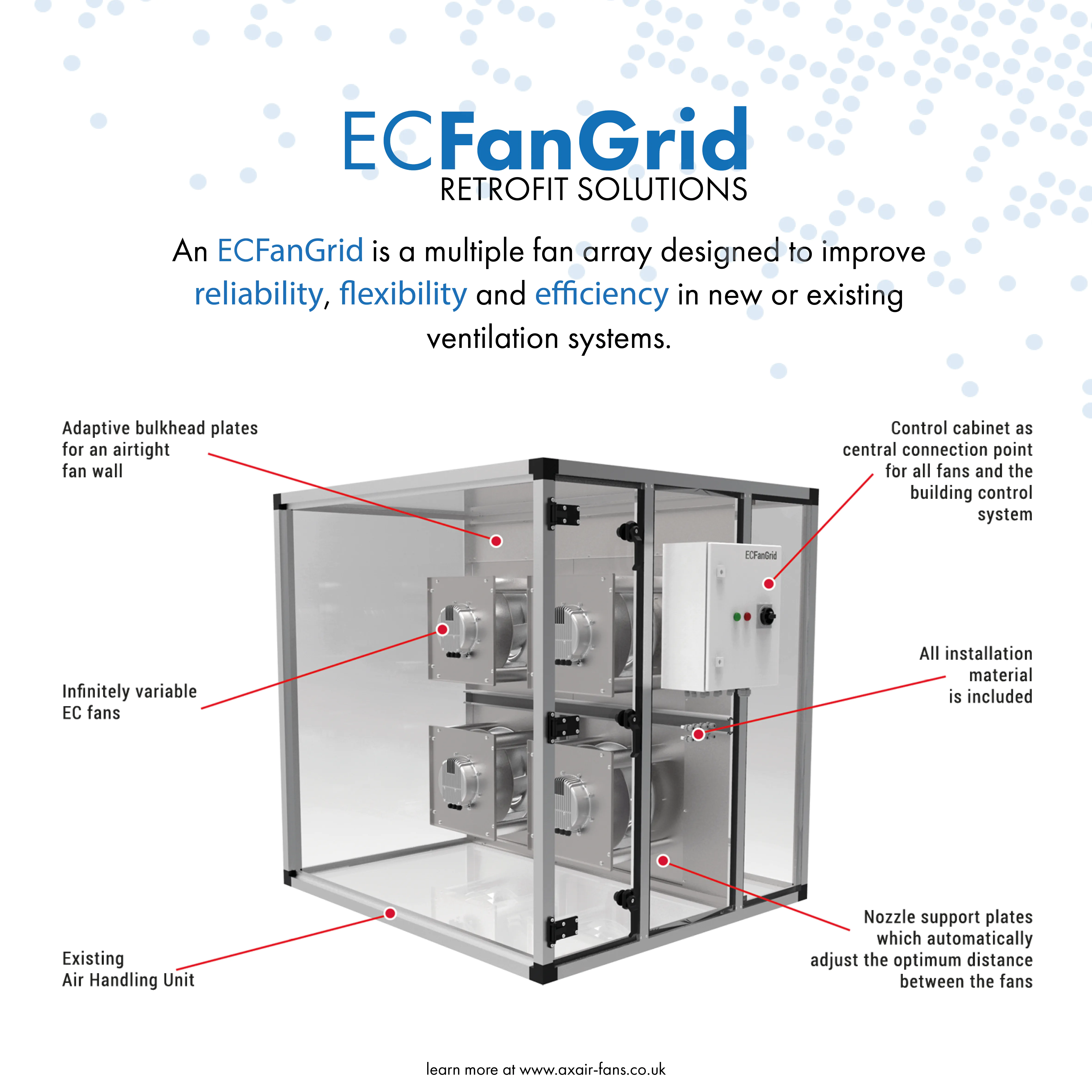

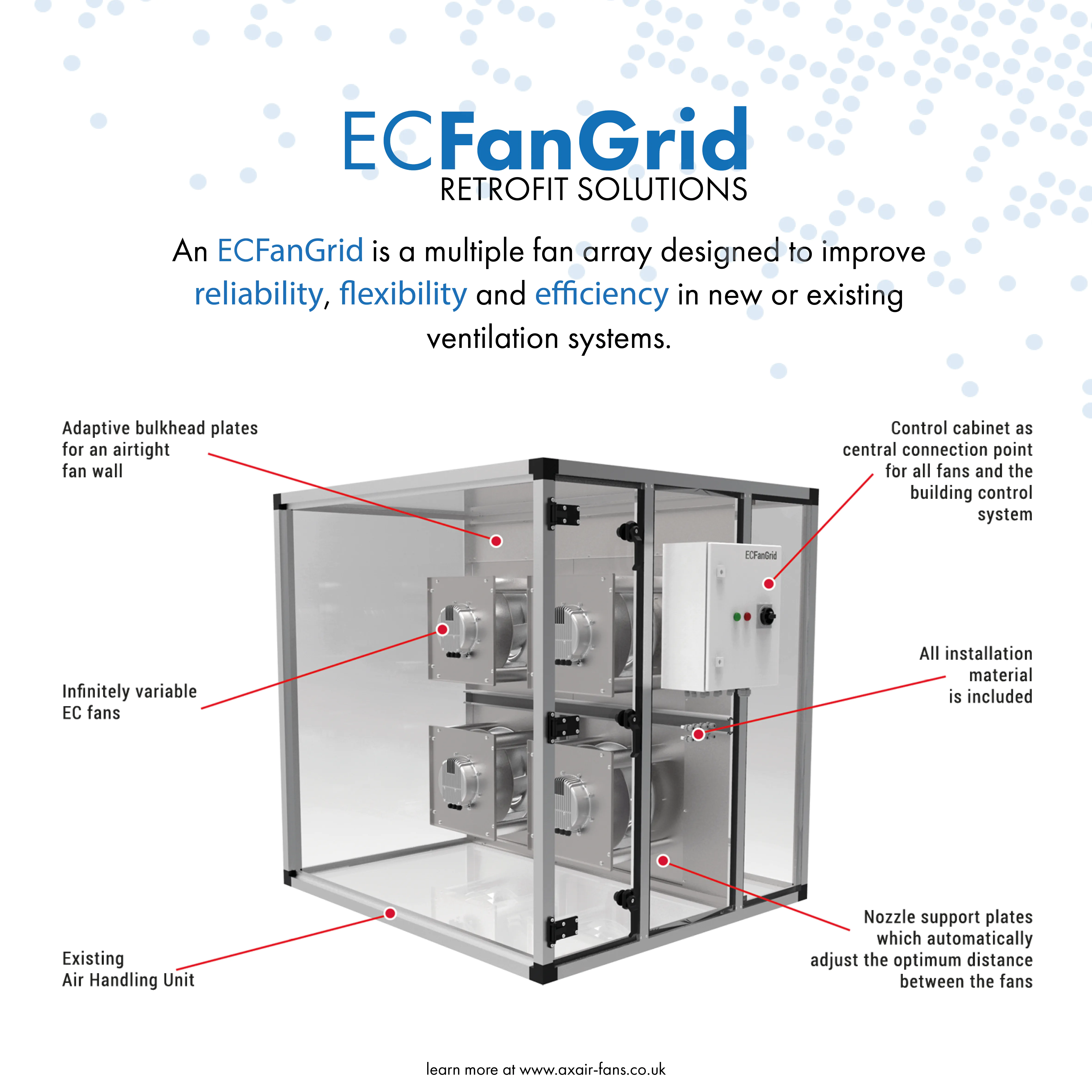

Suitable for new projects and as a replacement for large single fans in retrofit air handling units, modular backward curved centrifugal fans or EC plug fans are arranged in a multiple fan array grid construction which offers numerous advantages over conventional single fan technology.

If you would like us to specify an EC FanGrid for your application, need more information about installation, or general assistance please contact us on 01782 349 430 . Alternatively, complete an enquiry form or send an email to [email protected].

Lead the way to more energy efficient buildings by providing the best ahu retrofit solution

Unlike others in the industry, we combine knowledge of the market with customer needs and technical know how, as well as site visits, energy surveys, partnered installation where required, support with integration, control and post installation assistance. Our EC FanGrid Retrofit Solution is a simple, easy to assemble multiple fan array designed with energy efficiency at its core.

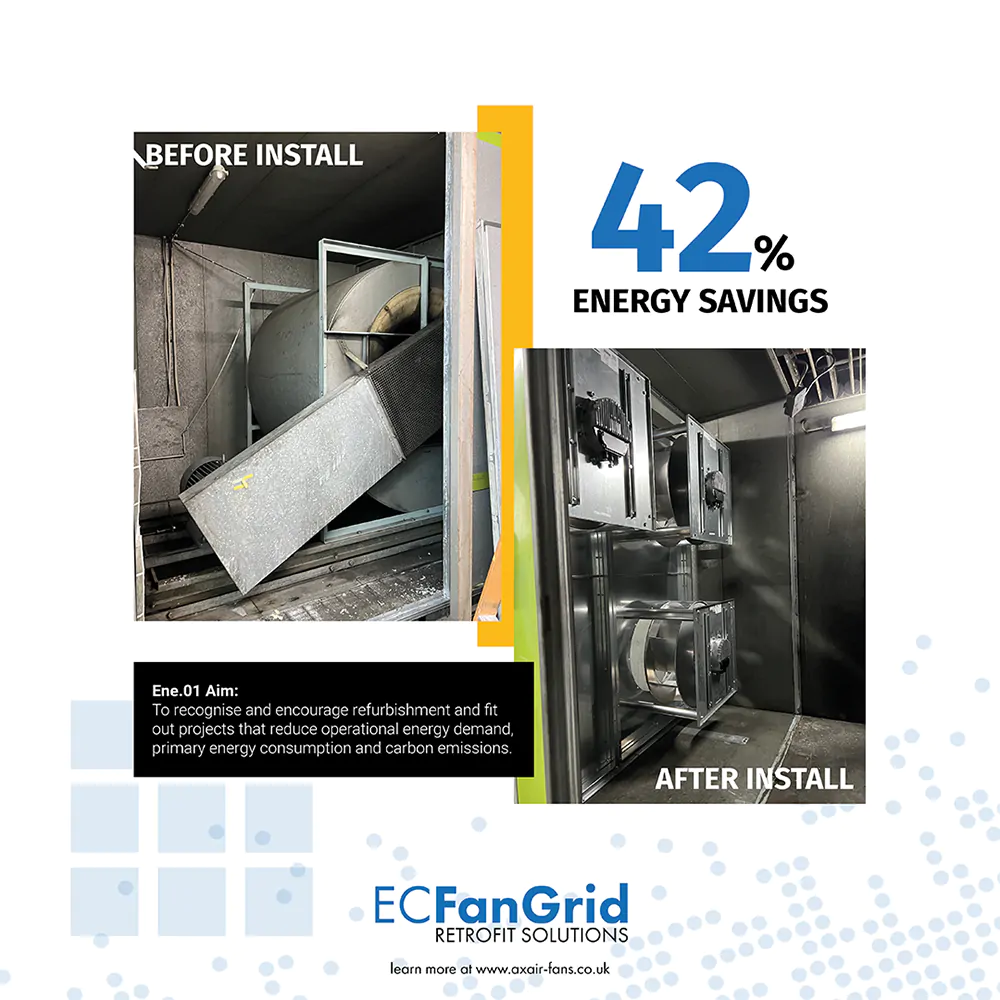

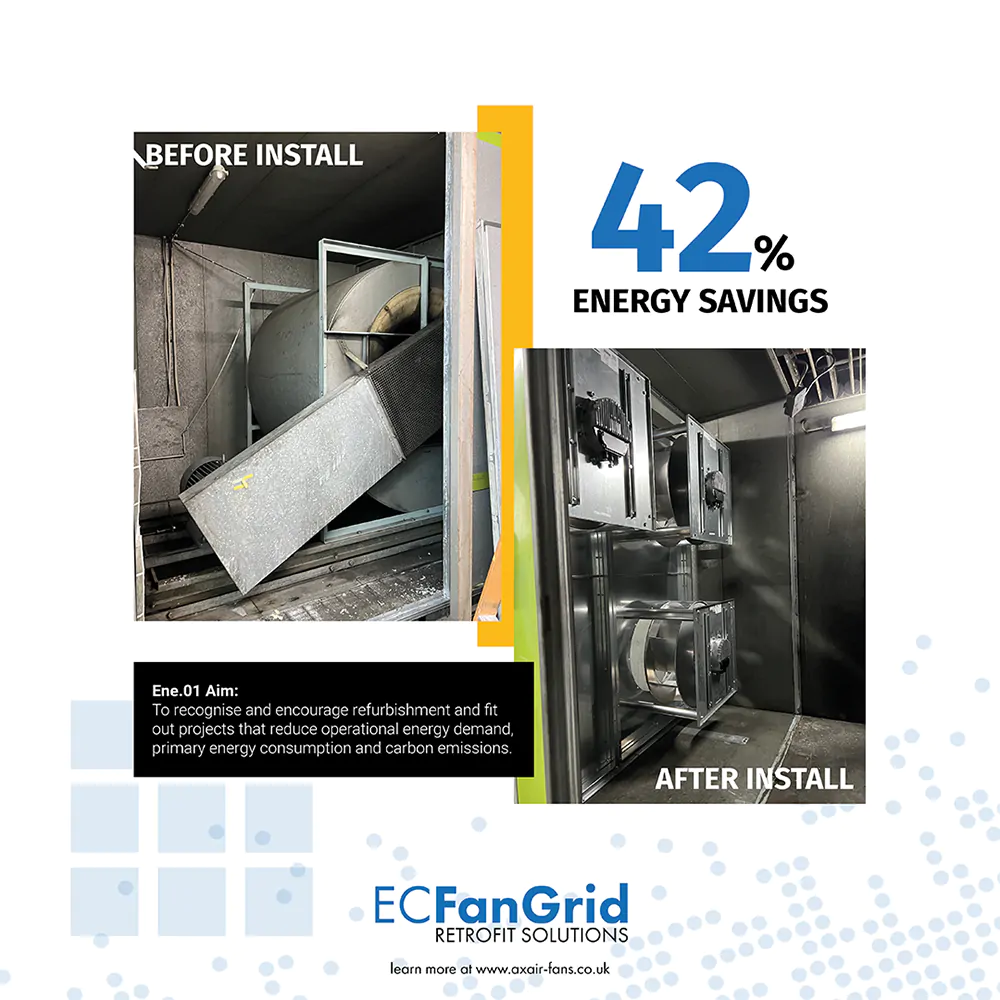

Typically 40% of a commercial buildings energy use comes from heating, ventilating and cooling with 50% of the HVAC energy consumption coming from fans. Savings as a result of moving from AC to EC occur from both improved motor efficiency and from optimising the overall system design. There is potential to achieve greater efficiency when the system’s operating range includes multiple plug fans running closer to their peak efficiencies, instead of one large fan controlled over a wide operating range.

The number of plug fans in each ECFanGrid system can vary according to the airflow requirements. For example, in a wall of nine fans in a 3×3 configuration where only seven fans may be required for normal operations to deliver the designed duty, the eighth and nineth space can be blanked off. If the demands on the AHU increase through building expansion for example, the blanking plates can be removed and one or two fans can be added to the grid to meet the new requirements.

The ECFanGrid provides superior reliability as a result of its built-in redundancy. When using a FanGrid, fan redundancy is one of the major advantages why it is beneficial to run fans in parallel within an air handling unit. Within AHU systems a second or subsequent fan unit would be operating in parallel with the primary duty fan. Both are then sharing the demand. Should the primary fan fail, the second fan would pick up the full load to achieve the required duty by speeding up.

In the world of HVAC the efficiency of industrial fan systems is often compromised by an ineffectively designed air movement system and poor efficiency. This is often accompanied by unwanted fan or air velocity noise making the whole system less than desirable. Case studies show that sound is not an issue when using an ECFanGrid, on the contrary there will be more possibilities to significantly lower noise. When using an ECFanGrid there are two major advantages to attenuate noise. First, the noise spectrum of smaller impellers contain higher frequencies, thus the wave lengths are shorter, allowing for the use of shorter attenuators. Second, the required length of the fan section in a typical air handling unit, using a single large radial fan can be reduced dramatically - in some cases up to 50%.

Unlike a traditional belt drive unit which covers a large floor space, the ECFanGrid is completely free of the floor. This means that maintaining the hygiene of the AHU is quicker, simpler and more effective. No dust is released into the supply air as there are no belt drives to degenerate over time. Component failure is quickly dealt with due to the modular nature of the ECFanGrid. For example, a single fan module could be replaced and the AHU back online within an hour of shut down.

Conveniently Flat Packed For Easy Installation

Due to the smaller component size, the ECFanGrid fan array solution is delivered on pallets to your nominated delivery address. The ECFanGrid can be walked through standard pedestrian doors by no more than two operatives; a significant factor in maintaining tight replacement schedules and reduces costs when compared to alternative solutions.

For convenience we offer our customers two flexible purchase routes:

- Supply of components only

- Supply of components and full installation

Talk to us about how our inhouse installation team can assess your site, design a solution and install an ECFanGrid on short time scales to reduce system downtime.

If you choose to go ahead with the ECFanGrid multiple fan array, and have your own installation team or contractor to complete the grid construction, we'll make the necessary selections based on your goals, and schedule a delivery that suits you. After that we're here for support on the phone or email as you require to ensure your set up goes smoothly.

If you're looking for a full turnkey solution, we're here to help with both fan selection, and installation. Discuss your requirements with our team and we'll ensure everything is installed with little downtime so you're up and running in no time.

Site Visits, AHU Project Validations, & Energy Surveys

For client peace of mind and to ensure that any problems can be identified and incorporated into your project specification as early as possible we can carry out a site validation survey. We don't have to but if there's not enough information or you're looking to meet specific project objectives, it is the right route to take.

Site and AHU validation surveys are POA and invoiced in advance of any project.

Learn more about each of these stages below:

If you're considering the ECFanGrid multiple fan array solution and want to show us around, or talk to us in more detail, we can arrange a site visit to ensure the ECFanGrid is logistically a reasonable solution.

This is not a charged for visit as we will not be taking any measurements at this stage, it's an opportunity to get to know our capabilities better while we can assess the physical condition of the building and its surroundings, and to determine your objectives.

To ensure that any problems can be identified and incorporated into your project specification as early as possible we can carry out a site validation survey.

We’ll assess physical condition, compliance and capacity. Site and AHU validation surveys are POA and invoiced in advance of any project quotations.

Why is this charged?

AHU validation surveys give us information that is required to make accurate fan selections and will determine if the ECFanGrid solution will be a feasible path for you to follow. It may be the case that the solution isn't the best option to achieve your project objectives, this data will show that and allow us to suggest alternative products, or alterative solutions from our network of air movement providers.

Once completed the data belongs to you, and as such as you can take this information to alternative providers to provide a quotation or solution. The validation survey shows both us and you exactly what can be achieved with the ECFanGrid integration to replace an existing larger fan unit or older AC fans.

If you’d like to record and compare the efficiency and CO2 reduction of your old and new system we’ll take measurements to allow you to present figures to those who need them the most. This can be done at the same time or on a different day than the site and AHU validation survey. POA.

If you need us to come to site we'll use our technical know how and our specialist equipment to show you the information we've gathered in a comprehensive and well presented report.

Minimising Environmental Impacts with BREEAM Credits

Outdated ventilation systems consume electrical energy at an alarming rate. BREEAM compliant air handling units make a significant contribution to healthy, efficient, carbon and cost saving greener buildings. BREEAM compliance is a UK recognised symbol of sustainability achievement, and is backed by an entire industry of committed organisations and individuals paving the way for market transformation.

Air handling units typically fall under scope 2 carbon reduction. Scope 2 emissions refer to the indirect GHG emissions associated with the production of purchased electricity, heat, or steam that a company or organisation consumes. AHUs consume electricity to power fans and motors, which result in indirect carbon emissions associated with the electricity used.

To reduce scope 2 emissions associated with AHU's, we focus on increasing the energy efficiency, and reducing carbon output of the unit. This is especially true if we're replacing large centralised single systems with old and inefficient belt driven fans. In the case of new systems, new multiple fan array air handling units, are designed to ensure fans and motors run closer to their peak efficiencies, thus contributing to a lower energy consumption and carbon emission output.

For example, EC plug fans used in our ECFanGrid retrofit projects in 2019, reduced CO2 emissions by 2980t in one year, with over 5987MW energy savings per year.

The average payback period on new ECFanGrid installations is between 2-5 years. If we have accurate data we can suggest average payback periods for your project.

To accurately calculate the payback period of an ECFanGrid, it’s a simple case of comparing the absorbed power for the existing system against the absorbed power for the ECFanGrid. To do this, a validation survey is undertaken and the volume flow rate and total static pressure of the existing fan is measured. The absorbed power of the fan system is simultaneously recorded. This data is then compared to the absorbed power figures of the ECFanGrid.

Building a sustainable air handling unit that is designed for a greener future is unique to each customer we work with. Our customer centric approach is solution led to ensure we specify, design and deliver the best air handling unit to help you to acheive your target BREEAM rating by contributing to credits in the following categories:

- Energy

- Health & Wellbeing

- Pollution

- Management

- Waste

While air handling unit manufacturers cannot themselves be BREEAM complaint, AHU units are designed to help a building meet BREEAM criteria and contribute to the sustainability of the building seeking certification. AHUs are evaluated against a number of criteria related to their design, installation, and operation.

Energy Efficiency:

AHUs are evaluated based on their energy efficiency and whether they meet specified energy performance targets. This may include criteria related to the use of high-efficiency fans and motors, variable speed drives, and controls that allow for efficient operation and maintenance.

Ventilation Rates:

The AHU’s ability to provide appropriate ventilation rates is evaluated to ensure that indoor air quality is maintained at a high level. This may include criteria related to air change rates, the provision of outdoor air, and the ability to scale up or down capacity as needed.

Noise Levels:

The AHU’s noise emissions are evaluated to ensure that they are within acceptable levels and do not negatively impact occupants’ health and well-being.

Maintenance:

The AHU’s maintenance requirements are evaluated to ensure that the unit is properly maintained and operating at peak efficiency. This also includes instructions for troubleshooting and maintenance.

Pre & Post Install Technical Integration Support

Go into depth with the ECFanGrid solution by learning more about spacing, how to calulate & attenuate noise, determine the need for seperators, control, constant pressure, ModBus RTU, electrical wiring, covering and handling failures and indepth explanations of test conditions by downloading our ECFanGrid technical white paper below.

Our team understand AHU's and the AHU market thoroughly, we'll talk you through solutions that best fit your requirements.

With specialist equipment at the ready we can assess current performance and let you know the difference a multiple fan array retrofit will make to the overall performance of your AHU.

We'll always look at your project to ensure your and our safety.

Axair ourselves cannot perform commissioning on your installed unit, but we can suggest some very reputable partners that we work with who can get this, and regularly servicing scheduled in.

691

Retrofitted systems

5987MW

Energy saving p.a

2980t

CO2 saving p.a

Turbulent Airflow?

Turbulent air flow path in your AHU? The ECFanGrid delivers a more even distribution of air velocity over the entire duct, significantly increasing the efficiency of the entire system.

Building Damage?

The smaller components of the ECFanGrid parts are easily portable through pedestrian doors by no more than two operatives. No damage or changes need to be made to the internal building fabric.

System Failure?

The auto response of the ECFanGrid to indiviual fan failure through redunancy, means you get protection against system failure, when one fan fails, the others pick up the duty.

Technical Installation Articles

Below you'll find indepth troubleshooting for your ECFanGrid installation. Download our whitepaper or contact our specialist team who will be able to advise on best practices.