Sewage & Waste Water Treatment

Polypropylene Fans for Water Treatment

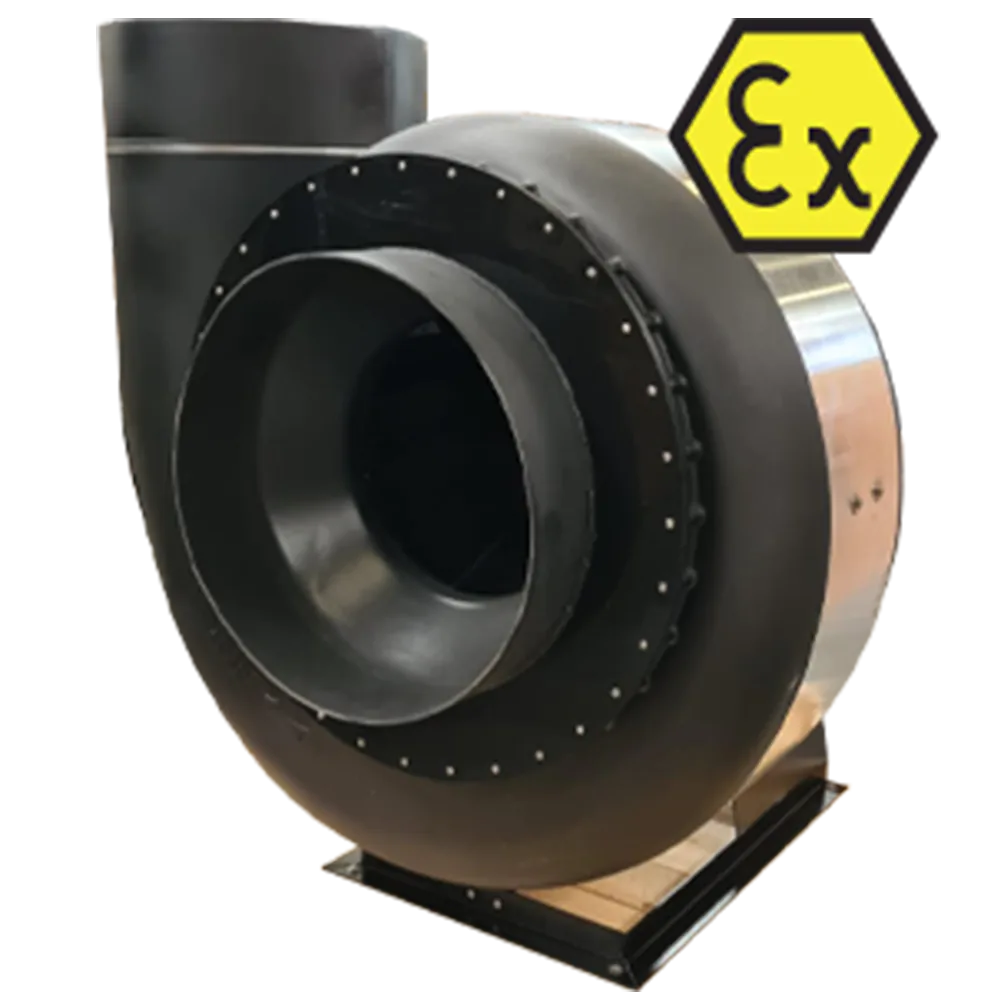

Corrosive Fans for Sewage and Wastewater Treatment Plants

Fans for waste water and sewage treatment plants are an important part of the water cleaning process. Water treatment companies in the UK face daily challenges in delivering water that is safe and reliable while protecting those working within the sector from hazardous gases, corrosive air and high temperatures. Polypropylene fans ensure safety and the extraction of gases, vapours and fumes in toxic and corrosive environments.

Where are Industrial Fans Used in Water Treatment Processes?

The first step of the water treatment process is ensuring that all wastewater reaches the UK’s sewage works via the drainage and into the sewers. It is then guided to the sewage treatment plant via underground pipes. Sewage that comes from pipes below the main sewer line, for example basement bathrooms that create difficulty for movement, may need a pumping station to help push the sewage in the right direction. At the sewage treatment plant the wastewater then goes through preliminary screening where debris such as nappies, wipes, plastics and gravel from the roads is removed.

The next stage is primary settlement where the wastewater is pumped into large sedimentation tanks to separate any suspended solids. The solid waste is heavy and therefore falls to the bottom of the tank forming a layer of sludge that can be removed. Once all the debris is removed, the wastewater is held in tanks where the activated sludge process takes place by pumping air in the tank, an area that encourages bacterial growth. As a result of this bacterial growth, the water passes over specialist filter beds containing masses of waste eating bacteria. The bacteria digest the organic matter breaking it down into harmless substances. The final step of the process, the tertiary treatment, is where the last few waste particles are removed. The water is already very clean at this stage but depending on where the water is required, further treatment of disinfection is needed and in some circumstances, nutrients have to be removed for environments that can’t handle excessive richness of waters.

How are our fans used during this process?

- After removing any materials that could damage the pumps such as grit sand or stones, industrial fans are used to recover fats and oil as froth.

- Air and oxygen help the growth of floc which removes organic materials in sewage treatment. Fans are used for combustion.

- Industrial fans are used to dry sludge to decrease the amount that needs to be incinerated, or for the produce of organic fertilisers.

- Industrial fans reduce temperatures and dissipate the generated heat throughout the water treatment process.

- Ozonisation of water – infusing ozone gas into water produces a biocide which destroys bacteria, viruses and cysts. A corrosive resistant fan capable of handling toxic fumes would be used to reduce the risk of fire and toxic air being released into the environment.

- Aeration, where air is circulated through the water to reduce the carbon dioxide produced by a treatment process. Aeration is also used to oxidize soluble iron and manganese, a chemical is added to convert any dissolved iron and manganese into the solid, oxidized forms that can then be filtered more easily from the water.

- Air floatation, where solids, oils and other contaminants are removed via the use of air bubble flotation.

- Organic air purification systems

- Corrosive resistant fans assist with water purification with the use of chemicals

- Filtration for emission into atmosphere

Other areas where installing the correct industrial fan is vital for the safety of staff and plant operation

- Testing laboratories

- Algae desiccation

- Air supply to boilers

- Cleaning process of contaminated air

- Transport of waste gases

- Specialist Odour Control

- Membrane housing

- Disinfection processes

- Sea water desalinisation

- Marine salt production

- Bulk storage of lime, talc, activated carbon, dehydrated sludge and ash

- Storage of chemicals

- Processing of cooling water

Water Treatment Processes

Sewage Treatment

Sewage wastewater treatment plants reduce pollutants in the water used by homes, businesses and industries before it is released back into the environment. The water built up from rainstorms is also a hazard to our environment, harmful substances can wash off buildings and road surfaces and run into our rivers and lakes. The survival of a wide array of species and plants living in the water relies on this treatment process to keep the water clean and habitable. Harmful bacteria are also removed from water preventing the risk of disease spreading. The inability to treat water efficiently would result is serious harm to the ecosystems and human health.

Sludge Treatment

Sewage sludge is the semi solid, solid or accumulated from the water treatment process. At sewage treatment plants the sludge is separated from the wastewater and treated so that it is safe to be recycled or disposed of. The sludge is either formed from the separation of the solids in the water or is created as a resulted of biological treatments to the water. These treatment plants often receive waste material contained in or removed from a septic tank from household on site wastewater treatment systems. Often sludges are combined for further treatment and disposed of.

Desalination Plants

Desalination plants produce water for drinking and agriculture on coastal regions. The process uses chemicals to remove excess salts and minerals from sea water, rivers, streams, wastewater, industrial feed and process water. A build-up of concentrated brine ( a high-concentration solution of salt) is produced in the process which would usually end up back in the sea so a pumping system would commonly be used to prevent any harm to the eco system and marine life. However, more recently brine has been used in various processes. In 2019 Engineers at MIT News completed a study to show that through a fairly simple process the brine from this process can be converted into useful chemicals -including ones for desalination process itself more efficient.