Air Handling Units - AHU's

We empower you to make the right

Industrial EC Plug Fan Selections

to Meet your Air Handling Unit Requirements

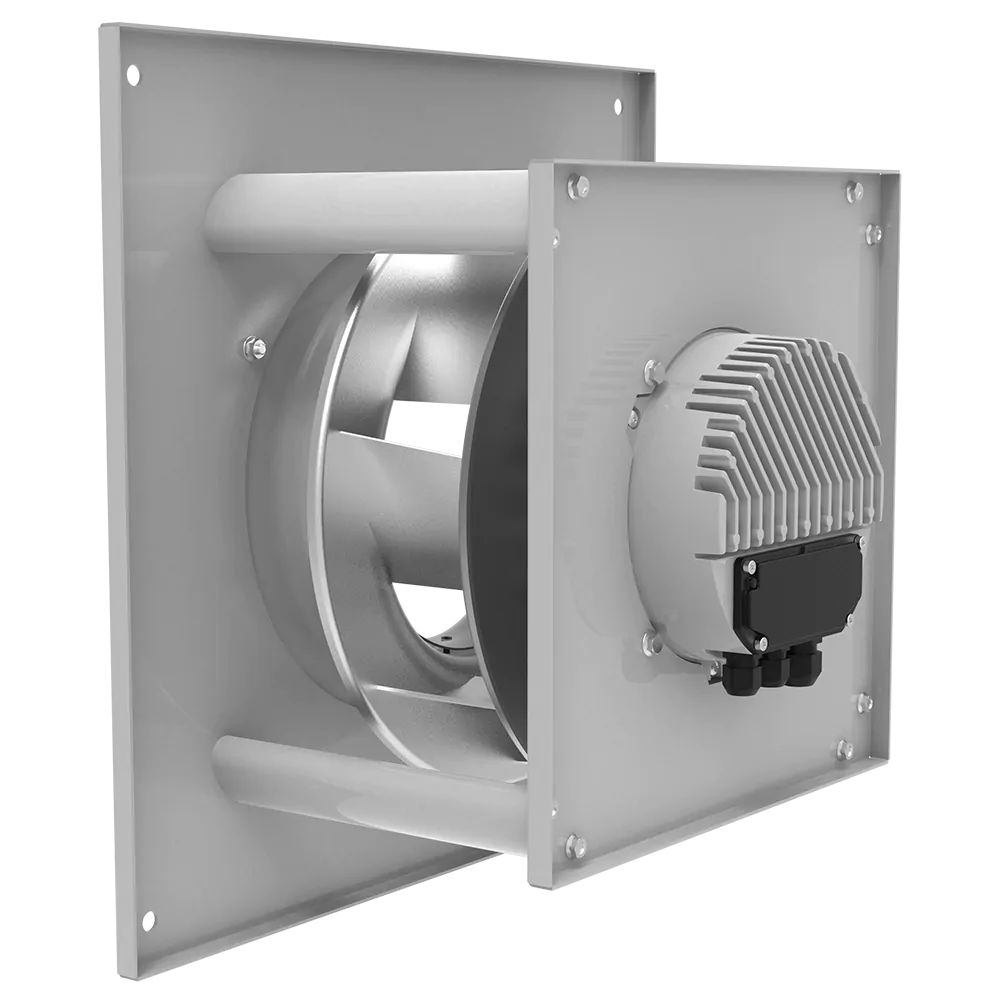

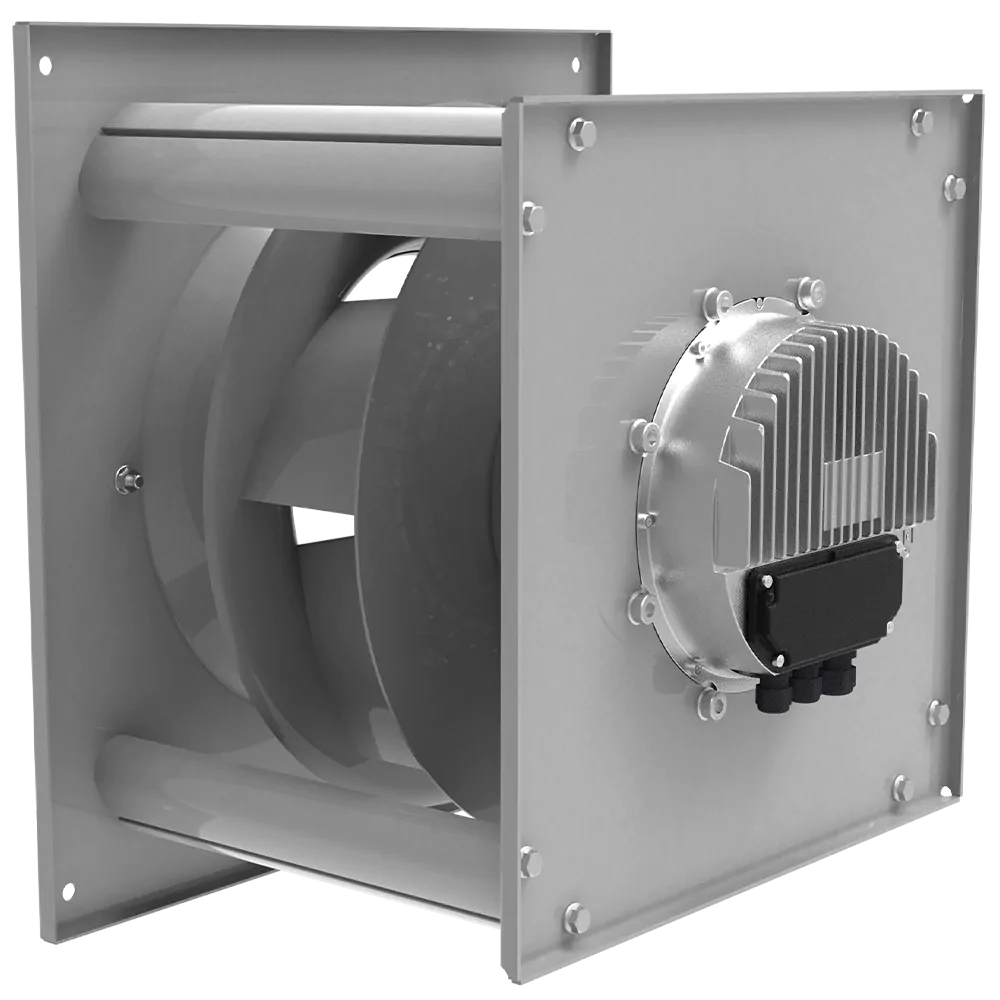

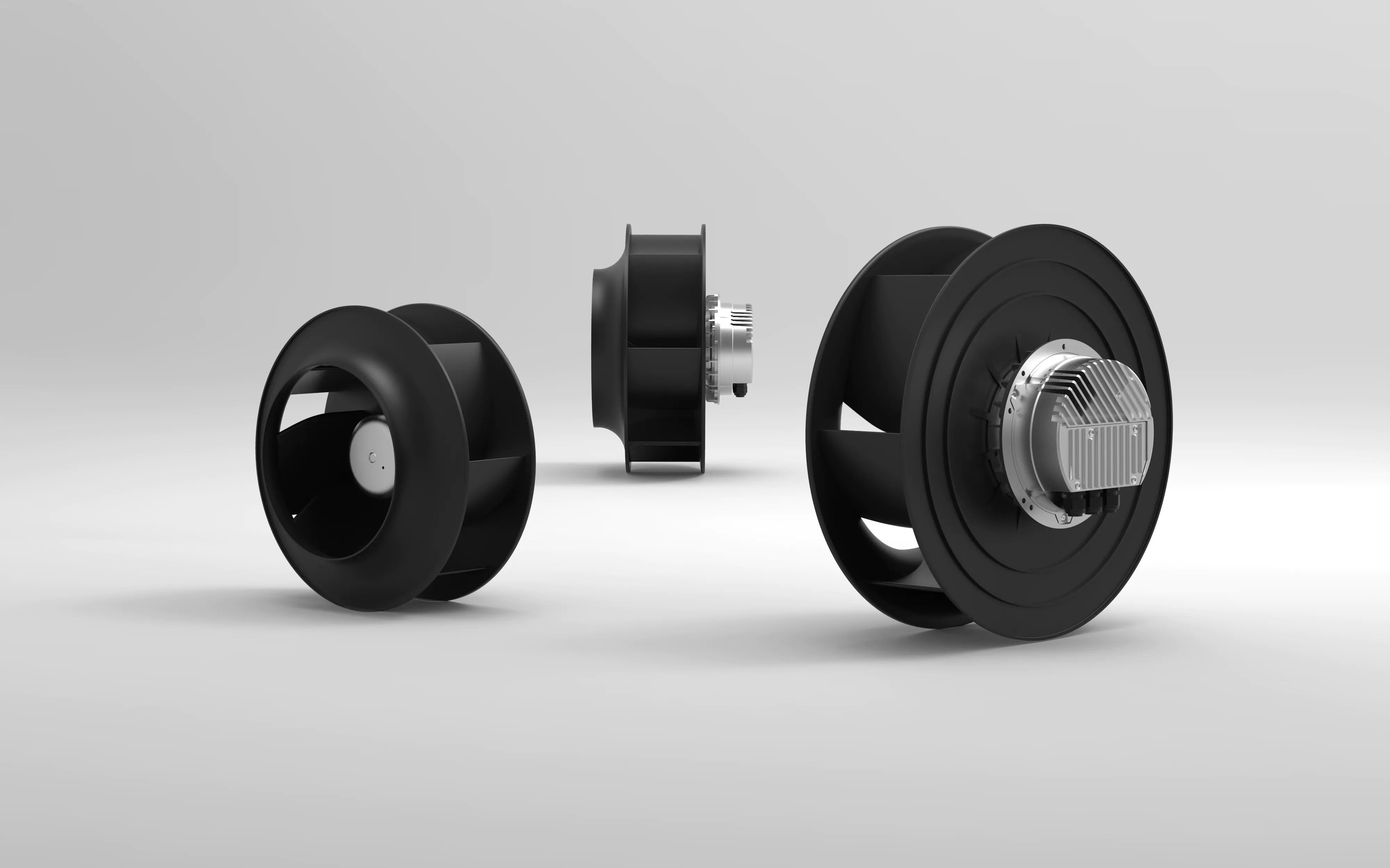

Better systems need better fan selections, so you should demand the full attention of technical fan experts to ensure you and your customers get the best. If you’re an air handling unit manufacturer and you’re looking for a solution to your AHU fans technical selection issues then you’re in the right place. Our Rosenberg centrifugal plug fans featuring application specific optimised impellers, are used extensively within major UK manufacturers air handling units or in AHU retrofits within multiple fan arrays. When you contact us for assistance, our EC plug fans are specifically selected to match your needs, not ours. We're revolutionising the industry, showing you a new way of working with suppliers in an old and antiquated industry so get in touch and see how we can make a positive impact to your way of working.

Learn more about Axair Fans

EC Plug Fans That Help Original Equipment Manufacturers to Build Better AHU Systems

An air handling unit is a factory-made bespoke case assembly manufactured by specialist ventilation OEMs. Though other materials are used, generally anodised aluminium or plastic coated galvanised steel (GSS) are used for the fabrication outer. Thermal and acoustic insulation is enclosed between the outer and inner skins to reduce noise. Within this outer GSS casing, EC extraction plug fans and drives sit inside to perform the main bulk of work for the ventilation unit. AHU's are found in medium to large commercial and industrial buildings and can be located on the roof, on the floors or within the basement. Multiple air handling units are situated across a building serving single zones such as individual floors or rooms. However in particularly old or high rise buildings, there may be one large AHU, usually located on the roof that will serve the entire building. This is now seen as an inefficient design, and in a goal to meet environmental targets, AHU's are assessed and upgraded all across the World. Learn more about BREEAM and AHU's here.

- AHU Case Studies We're Proud Of -