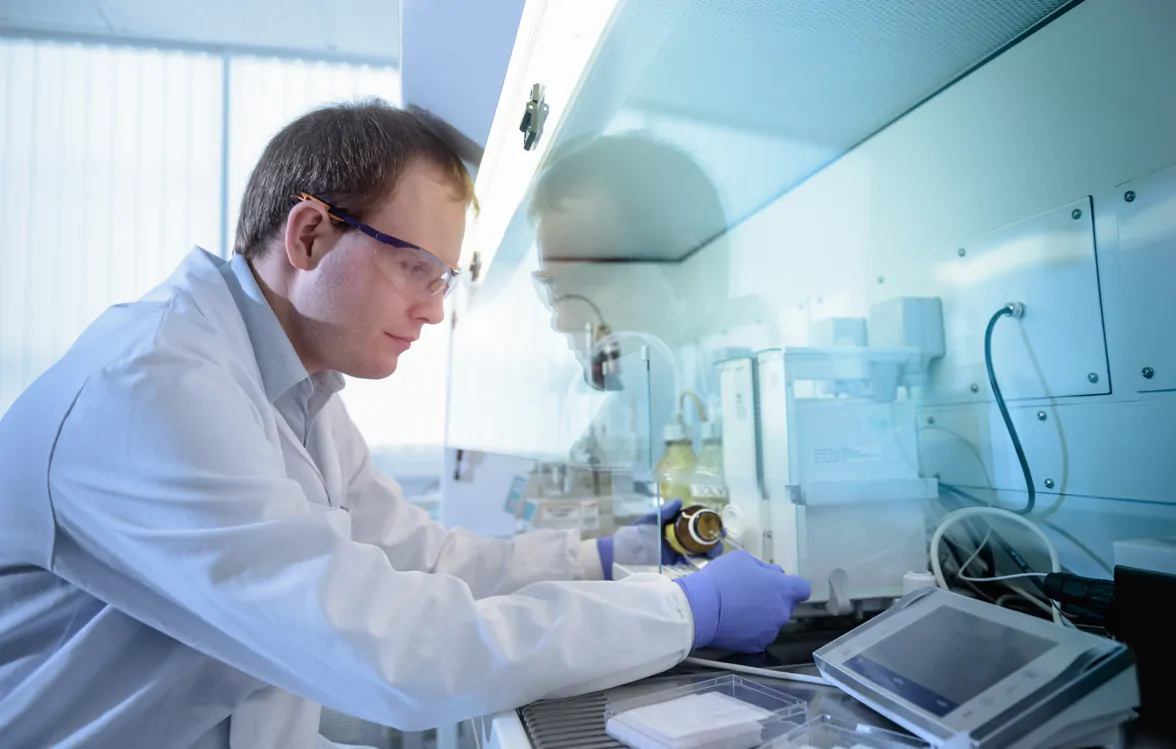

Our team of technical industrial fan engineers are experts in their field, we're proud that we

We Work With A Diverse Range of UK Customers

Over 30 years in the UK fan market means we've learnt how to deliver the best to our HVAC and air movement OEM's, contractors, installers, consultants, specifiers, distributors and end users, regardless of their application. In fact one of our most valued skills, is in understanding almost every industrial fan application, to make sure you get the best integration advice and fan selection in the UK fan market. Our efficient enquiry handling means you'll always deal with an experienced person who understands your application, while experiencing our unique streamlined process, with no unnecessary handovers, focused on getting it right first time. Every interaction you have with Axair, will exemplify why we're fast becoming the independent fan supplier of choice in the UK fan market.

300+

Technical Articles

56,000+

Industrial Fans

30+

Years Experience