Fume Extraction Systems

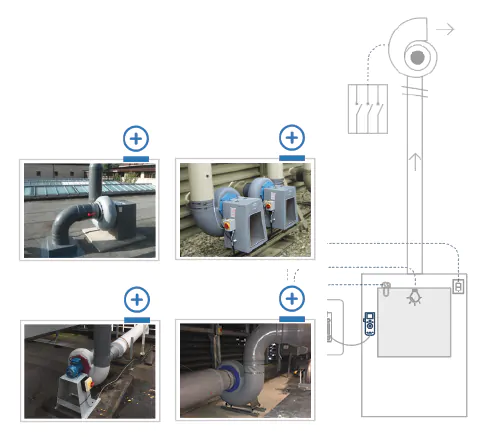

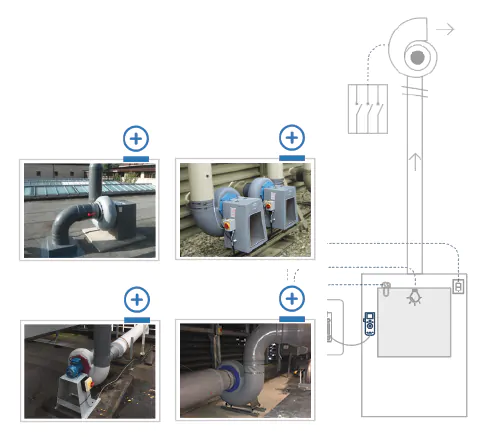

We select the best industrial polypropylene fume fans for the safe and efficient use in

Industrial Corrosive Fume Extraction Systems

We're pride ourselves on technical excellence and indepth knowledge of fume extraction fans and components. By working closely with our manufacturers and those in the laboratory & industrial fume extraction market we are confident that we can offer the most effective ventilation components, advising when installation accessories could save time and money.

Typical Industrial Fume Extraction Applications

Corrosive fume extraction fans play a fundamental role in many industrial fume applications.

Fume Cupboards

Fume cupboards are widely used to prevent harmful vapours being released into a building during experiments. Corrosive fume extraction fans vacuum the toxic air from the cupboard and up through a ducting system during the experimental process. This eliminates any chance of the vapours escaping and forces them straight out to the atmosphere.

School Fume Fan Pack | Ductless Ventilation In Fume Cupboards

Water Treatment

Water treatment companies have a duty to follow strict regulations in regards to the processes and health and safety of workers. Several treatment processes in this industry use a high measure of chemicals and face high temperatures and gas production. Efficient ventilation is key to providing a safe working environment and ensures machinery and systems run safely. The plant room or dosing cabinet requires a fume extraction fan to vacuum harmful particles out to atmosphere to prevent any health and safety risks.

Corrosive Fume Extraction in the Water Treatment Process | Wastewater Treatment Ventilation: Polypropylene vs. Stainless Steel and GRP

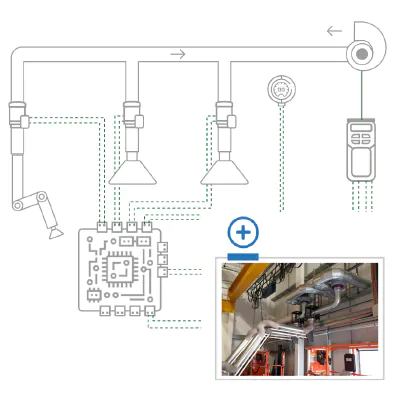

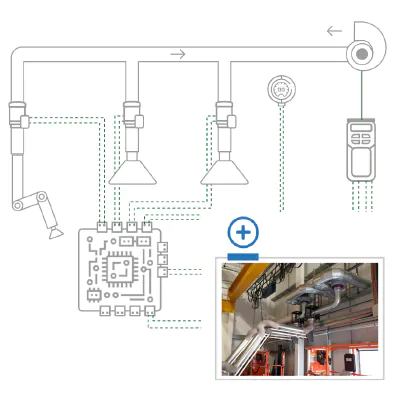

Local Exhaust Ventilation

The fan in the system must be the right size and type to deliver sufficient extract from the hood. The fan is the engine that powers the extraction system where air is moved from the contamination area in the hood, conducts along the ducting to the discharge point where the extracted air is released into a safe place. This may also need to be filtered before been released. Centrifugal fans are the most commonly used fans for fume extraction system, generating large differences in pressure and can produce air flows against considerable resistance.

Anaerobic Digestion

Anaerobic Digestion is a sustainable waste treatment practice in which microorganisms break down biodegradable organic waste in the absence of oxygen. Reclaiming potential energy from the waste in the form of biogas provides the option of nutrients being recycled back to land. Digestion tanks are confined spaces designed to seal out oxygen and therefore pose potential threat to human life upon entry. Anaerobic digesters should never be entered where there is not an extensive ventilation system in place with the use of mechanical fans. Natural ventilation is not enough to provide the required amount of breathable air. Fume extraction fans also remove the toxic gases that are produces during the treatment processes. These gases would otherwise sink to the bottom of the tank and remain there which poses the risk of a fire or explosion.

Fans For Anaerobic Digestion | ATEX Fans in Agricultural Silos

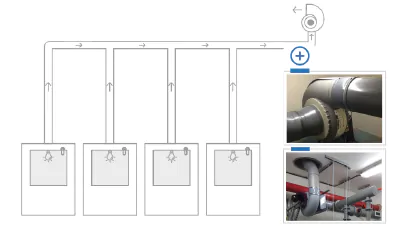

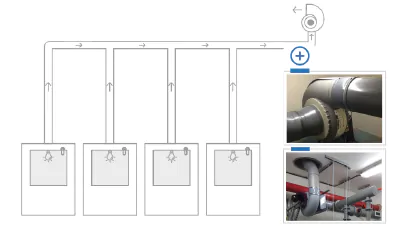

Manifold Systems

The fan in the system must be the right size and type to deliver sufficient extract from the hood. The fan is the engine that powers the extraction system where air is moved from the contamination area in the hood, conducts along the ducting to the discharge point where the extracted air is released into a safe place. This may also need to be filtered before been released. Centrifugal fans are the most commonly used fans for fume extraction system, generating large differences in pressure and can produce air flows against considerable resistance.

Patient Isolation Rooms

Patient Isolation rooms control the airflow in the room to reduce the spread of infection. It is vital that the correct exhaust ventilation system is in place to prevent infected particles spreading to other patients and members of staff. It is important that the fan is situated in the right place where it can be most effective and that it provides the right amount of air flow to maintain the correct pressure needed.

Mortuary & Autopy Rooms

Adequate ventilation is compulsory in a mortuary and post-mortem room to control the spread of infection and to control the release of odours. Drawing the air into the mortuary at a high level and exhausting it out at a low level is the preferred method. Down draught tables are effective in minimising the risk of exposure to infections by directing the airflow to the floor. There does need to be an efficient extraction point at floor level for this design to be effective.

We Consider all elements of fume applications, for better fan selections

To facilitate the effective installation of our corrosion resistant polypropylene fans, Axair supply a wide range of high quality accessories including AV mounts, starters, relays, inverters and weather cowls. Download the datasheets for the full range.