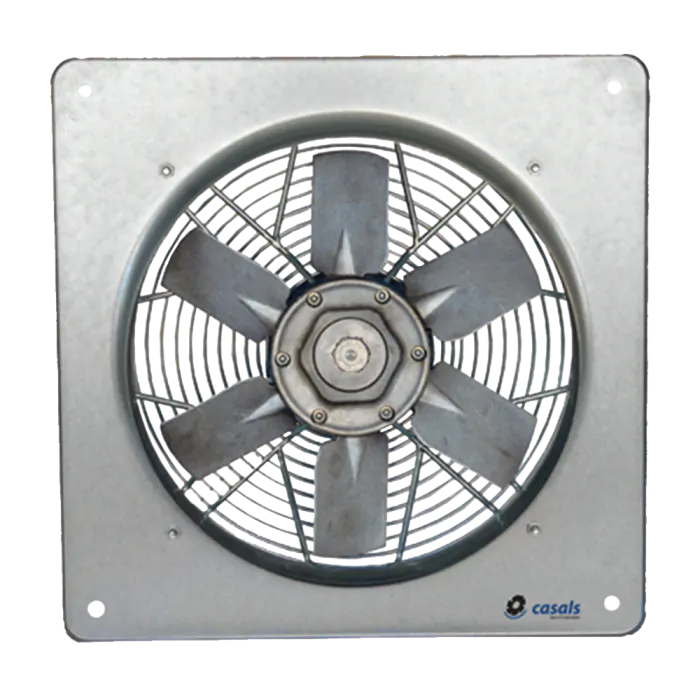

Stainless Steel Fans

Hygienic, Higher Strength & Lower Maintenance 304 SS Fans

Stainless steel is a corrosion resistant steel that has many properties that make it advantageous for industrial fan construction for use in niche applications. Resistant to corrosion and high temperature applications, stainless steel fans have higher ductility, higher strength and hardness, require lower maintenance and are generally attractive in visible applications. In food applications, stainless steel fans offer the most hygenic option, preventing mould and bacterial forming, while being more resistant to rust from frequent washdowns.

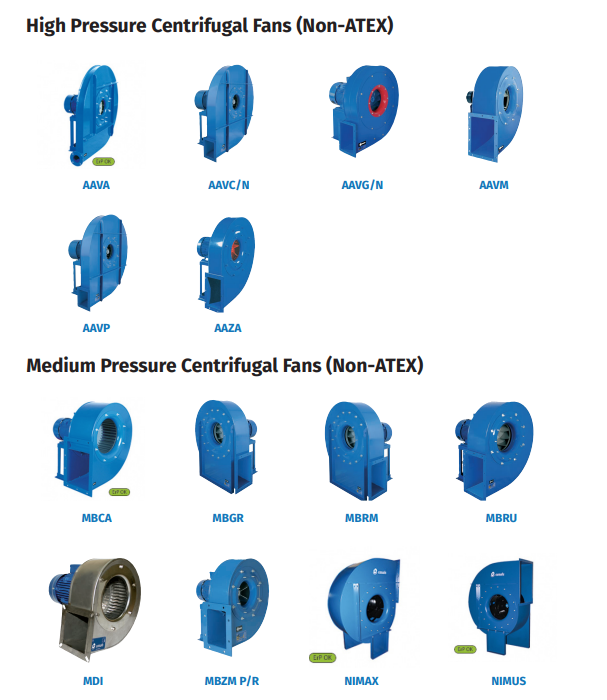

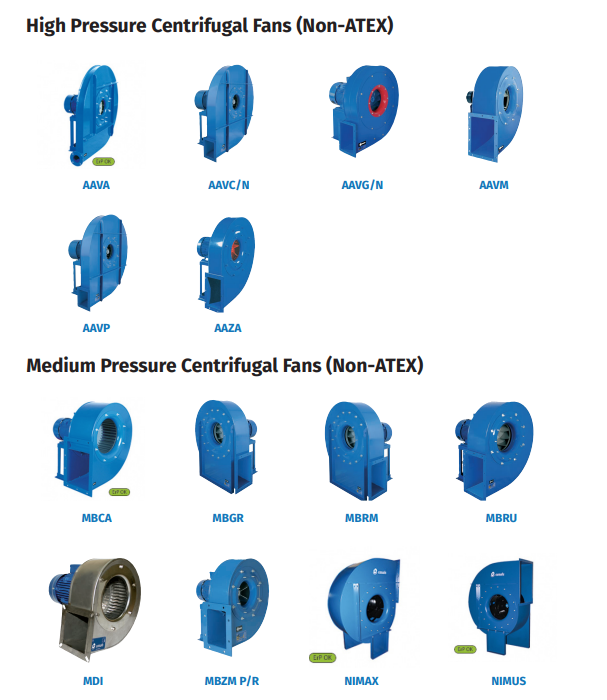

If stainless steel is not the right construction material for your application, we'll let you know our thoughts and offer an alternative from our wide range of axial and centrifugal fans in other construction materials, all available on competitive lead times.

Stainless Steel Fans That Match Your Application Needs

How much of the industrial fan is manufactured from stainless steel, depends on your application requirements. Choose to have only the internal parts in stainless steel – ideal when only the parts carrying corrosive air or in the airstream, need to be enhanced. Or choose to have the entire fan – the casing and internal parts – manufactured from stainless steel, ideal when the outer parts of the fan will be situated in the corrosive air.

304 stainless steel is a corrosive resistant metal that offers low maintenance while withstanding high temperatures. It’s robust and easy to clean making it ideal for intensive cleaning cycles. Particularly where plastic fans may be less suitable due to their size or inability to reach a particular airflow or pressure duty.

Grade 316 stainless steel has high amounts of chromium and nickel. 316 also contains silicon, manganese, and carbon, with the majority of the composition being iron.

316 stainless steel is often considered one of the most suitable choices when selecting an austenitic stainless steel for marine applications.

Other common applications of 316 stainless steel include:

- Chemical processing and storage equipment

- Refinery equipment

- Medical applications

- Marine environments, especially those with chlorides present

- The food industry

We offer a standard or electropolished finish on all of our 304 or 316 stainless steel industrial fans for use in corrosive air or food processing applications. Some customers prefer the aesthetic look of a polished stainless-steel finish while others want a product suitable for purpose without the need to look so polished.

Stainless steel has built in corrosion resistance due to the amount of chromium present in its composition. Stainless contains a minimum of 10.5% chromium, this chromium reacts with the surrounding oxygen very quickly and forms a thin oxide layer on the steels surface. The chromium oxide clings to the steel and acts as a protective barrier. The oxide is known as a passive film which seals the iron in the alloy, away from the air and water In the environment. This gives the stainless steel its rust resistance. Stainless steel can rust in certain conditions such as specific chemicals or grease – the exact reason we ask so many questions to determine if a polypropylene corrosion resistant fan is more suitable.

Enhanced Corrosion Resistance

Stainless steel has built in corrosion resistance due to the amount of chromium present in its composition. Stainless contains a minimum of 10.5% chromium, this chromium reacts with the surrounding oxygen very quickly and forms a thin oxide layer on the steels surface. The chromium oxide clings to the steel and acts as a protective barrier. The oxide is known as a passive film which seals the iron in the alloy, away from the air and water In the environment. This gives the stainless steel its rust resistance.

Stainless steel can rust in certain conditions such as specific chemicals or grease – the exact reason we ask so many questions to determine if a polypropylene corrosion resistant fan is more suitable.

Some types of stainless steel are more prone to corrosion than others, depending on the chromium content. The higher the chromium content, the less likely the metal will rust. But, over time and if not maintained correctly, rust can and will develop on stainless steel.

Optimal fan materials for applications with stringent hygiene requirements such as the food industry, where the need for regular wash downs can cause rust and fluctuations in ambient air conditions whether through temperature changes or condensation.

ATEX Stainless Steel Fans

Our stainless-steel corrosion resistant fans are suitable for high operating temperatures, contaminants, or chemicals and even zone 1 ATEX variants for explosive atmospheres. We’ll always ensure we provide you with a fan in the most suitable construction materials for your specific application. Our ATEX fans are suitable for zone 1 and 2 gas applications, or zone 21 and 22 dust environments, inline with the current ATEX Directive and as dictated in the legislation.

Fan selections will be made in line with DSEAR approved hazardous area classifications dictating the ATEX gas and dust zones and temperature ratings based on the end user’s specification. Learn more about the importance of hazardous area classifications here.

Choosing an ATEX fan requires a technical astute consideration of the environment the fan will be operating in. In explosive gas environments, the flammability and volatility of the gas, and the frequency of its presence influence this decision.

Learn more about ATEX gas zones here.

Starch powder, like many food-based powders used in the food processing industry, has the potential to be explosive. The conductive and combustible nature of the powders or grains used in the process means that there is a risk of catastrophic explosion, as even a small explosion could cause more powder to become airborne and in turn ignite.

Sometimes your application will call for an alternative material to metals, this may be due to corrosive fumes, a lead time that must be met, or it may just make sense on smaller duties. Our ATEX polypropylene fans are carbon loaded to effectively dissipate static discharge and reduce the risk of ignition. Learn more about the range here. We'll let you know what we think is the best solution for you based on the information you present us with.

ATEX fans vary in their construction when compared to regular industrial fans, in fact there are regulations that dictate the certified design of these components. Ex h signifies that a fan has been constructed in line with this regulation, showing that materials are non sparking, that the correct clearances have been adhered to and that in the event of rubbing or malfunction, no fricition will occur from mismatched unpermissible materials. All our ATEX fans are carefully contructed to adhere to all explosion market legislation.

Learn more about permissible materials here.

Move Corrosive Air Effectively on Smaller Duties with a Polypropylene Fan

With an impressive range of corrosion resistant fans, if stainless steel is not chosen as the best construction material for your application, the SEAT polypropylene range may be suitable. Our team will assess what you need and let you know what makes sense.

Examples of polypropylene chemical resistance can be seen in the table below. If you require more information on our polypropylene fan range or its resistance to specific substances, our team of engineers can support you with selecting the correct fan for your project.

View the resistance information here.

It is important to consider which type of material is best suited to a corrosive application. Stainless steel fans with a marine grade finish have added corrosion protection and could be a more suitable option in applications that utilise oxidising chemicals especially as strong oxidising chemicals may cause damage to polypropylene. By talking to a specialist fan supplier, they will consider environmental factors to determine the material type that offers the most suitable characteristics.

Ventilation systems in corrosive atmospheres must ensure a safe operation to transport airborne chemicals, reduce rust and corrosion of equipment situated in corrosive air, and to eliminate chemical exposure to the people in the building. For example, the use of highly toxic chemicals such as formaldehyde within mortuary facilities must be closely monitored to ensure the exposure limit is kept to its minimum safety guideline. Installing the correct fan is vital for achieving optimal system effectiveness, and compliance with safety regulations.

View the chemical compatibility table Here.

Zone 2 gas environments are the ideal choice for ATEX polypropylene fans. Available on short lead times and resistant to a huge range of chemicals, view the range here.

Hygienic Stainless Steel for Food Applications with

Conductive and Combustible Gases or Dusts

Starch powder, like many food based powders used in the food processing industry, has the potential to be explosive. The conductive and combustible nature of the powders or grains used in the process means that there is a risk of catastrophic explosion, as even a small explosion could cause more powder to become air born and in turn ignite. Our ATEX fans are suitable for zone 21 and 22 dust applications inline with the current ATEX Directive and as dictated in the legislation, fan selections will be made in line with DSEAR inspection ATEX gas and dust zones and temperature ratings based on the end user’s specification.

Case Study: A Sweet Outcome

Info here about marine and offshore cas study of focus etc etc etc.

Food Processing Applications

Washdowns, Temperature Changes and Condensation Protection.

Stainless in Water Treatment

Infor here about marine and offshore case study of focus etc etc etc.

Marine & Offshore

Corrosion Sea Water and Harsh Environmental Conditions.