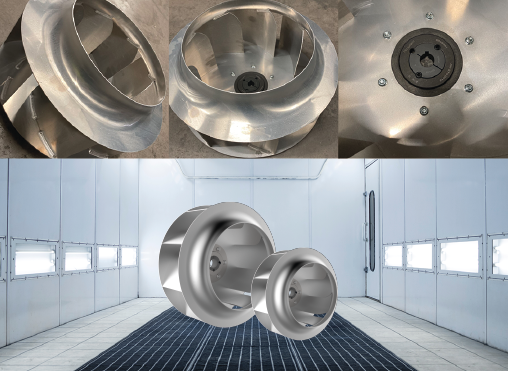

Aluminium Impeller Only Solutions

Combine your own Motor with High Quality Aluminium Impellers

We offer a range of aluminium impellers without motors from key European manufacturing partner Rosenberg. Our customers benefit from the most competitive lead times as we have a policy of holding stock of our most popular sizes so we can meet the demands of the industry. Flexibility is key in terms of performance and lead times allowing you to manage build schedules without having to worry about due dates slipping and build times becoming unmanageable.

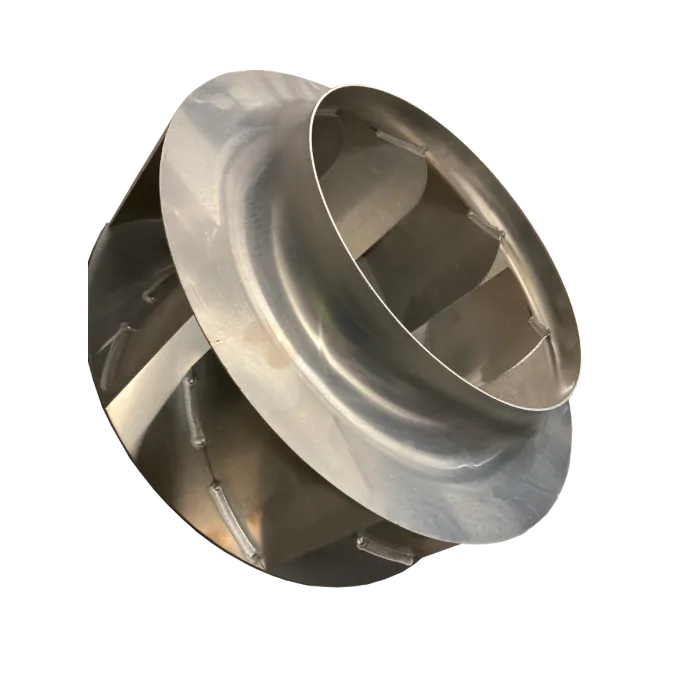

The lightweight range of R63 impellers without motors can be built into a range of fan constructions to suit the application. This can often make for a less cumbersome build as no workaround a fan motor is required. Customers generally source their own motor supported by a list of suitable motor sizes suitable for each impeller size.

We carry a popular range of sizes of Rosenberg impeller from 355mmØ up to 800mmØ.

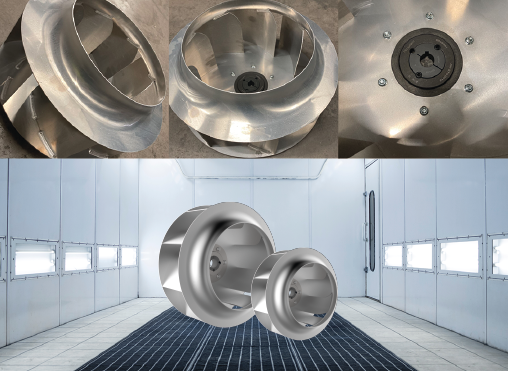

Critical Components in Surface Finishing & Spray Booth Applications.

Choosing a fan that can deliver a precise airflow, and a consistent pressure in and out of the spray booth, is critical when removing fumes and overspray, ensuring an adequate change in make up air. Axair has supported spray booth manufacturers for over 30 years, providing low noise, low weight, fan and impeller solutions.

The lightweight aluminium material of our W series backward curved impellers make them much easier to transport and install than competitor steel alternatives.

All LRHF W series impellers feature 8 backward curved blades and are dynamically balanced according to DIN ISO 21940-1 at least with quality level G6.3.

All impellers are supplied with aluminium hubs (Bgr.250-710) and taper lock steel hubs (Bgr.450-710). Our team can advise on the motor and shaft size that are suitable for the impeller we choose, ensuring it meets your operating point.

By sourcing the impeller and the motor seperately manufacturers are able to place the motor out of the airstream and choose ATEX motors where applicable for additional safety. The onus is on the manufacturer to determine the zone that the unit will be operating in.

LRHF Impellers

We advise clients to use the LRHF range of aluminium W series impellers from our manufacturing partners Rosenberg. In choosing the right impeller you can precisely match the size of the motor and fan performance for each booth so that the fan operates at performance and dBa levels within specified levels.

Our industrial range of impellers adhere to industry standards and specifications, meeting the requirements of both standard and custom manufacturing plants. Available on short lead times from 250-1000Ø.