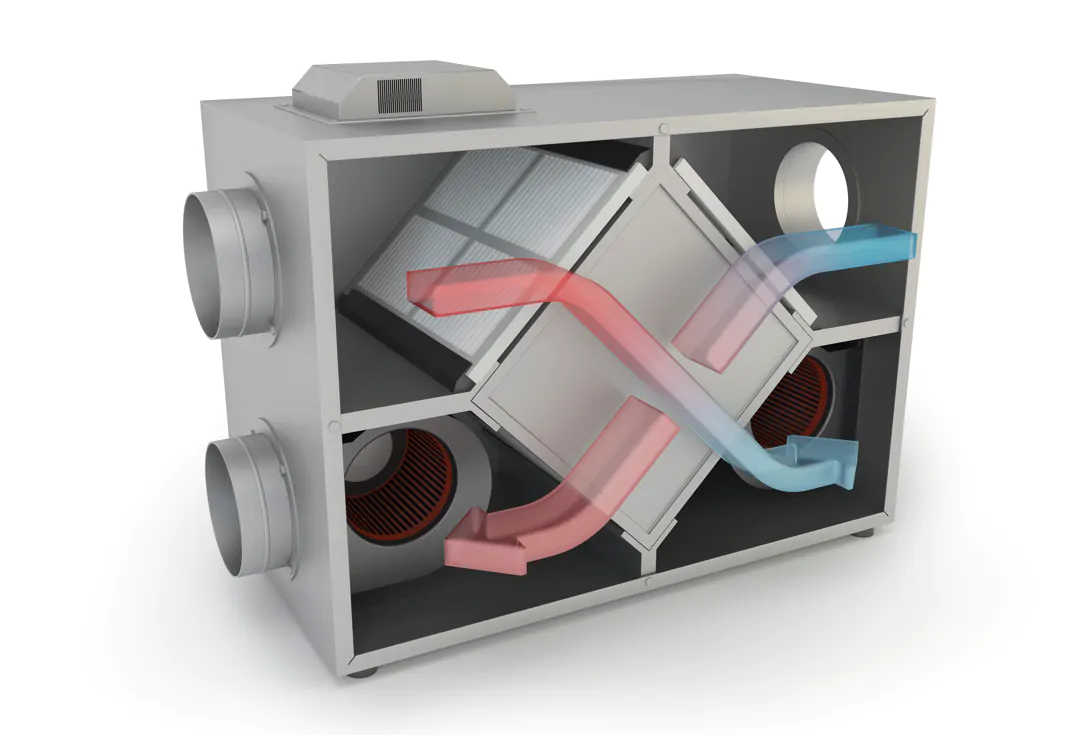

Heat Recovery Systems

Extract stale, moistened air in tightly closed buildings, and deliver a balanced airflow with

Constant Volume Fans for Balanced MVHR Ventilation Systems

High-cost savings and better indoor air quality are just a few of the key advantages of energy efficient refurbishments and new building design using controlled ventilation with heat recovery. A ventilation system with heat recovery should always be operated in a balanced way. This is the only way to ensure long-term heat recovery efficiency of the ventilation unit, achieving energy savings compared with exhaust-only systems. Devices with automatically balanced and pre-set volume flow rates can secure a balanced operation on a permanent basis, reducing the ventilation heat losses and preventing structural damage through condensation because of trapped humid indoor air penetrating the thermal building envelope.

Learn more about Axair Fans