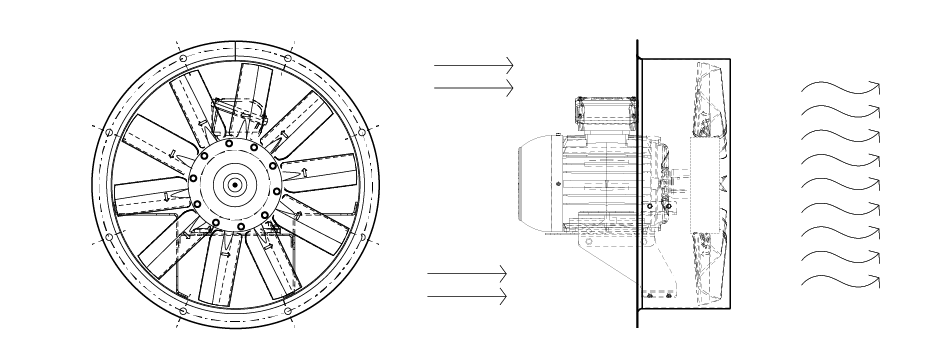

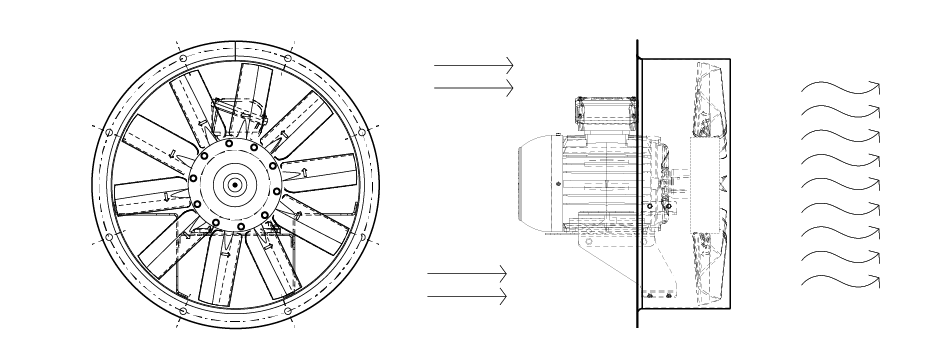

HBX Short Cased Axial Fans

Suitable for ATEX Gas Zone 1 and Zone 2, or Dust Zone 22

Manufacturing Features:

ATEX Certified Construction: Ex h.

Plate axial fan with a circular reinforced frame with a powder coat polyester resin to increase corrosion resistance.

Motor-impeller assembly through modular system with cast aluminium impeller.

ATEX standard asynchronous motor

ATEX certified: II2G Ex ec, II3G Ex eb, III3D Ex tc, Ex tb

IP55 protection and class F insulation

Manufactured with standard voltages: 230/400V 50Hz in 3~ motors up to 4kW and 400/690V 50Hz for higher powers.

HBX Short Cased ATEX Axial Fans with Certified Sparkproof Rings

The HBX range of short cased axial fans with adjustable cast aluminium blades and protected copper or aluminium inlet sparkproof rings provide higher volume airflow rates whilst also offering explosive protection in zone 1 and 2 ATEX gas or zone 22 dust environments.

Additional measures provide a high level of protection “b”. Equipment is designed and manufactured with components which reliably prevent ignition sources being generated internally such as static discharges or unacceptably high temperatures, sparks and arcs both on the internal and on the external parts of the motor. Suitable for zone 1 area use.

The enclosure is certified and constructed as Explosion protected according to the increased safety standard. The philosophy with Ex eb is to provide an impact resistant enclosure and also to ensure that its contents are certified such that they will never produce sparks, temperatures or current creepage that could ignite the flammable atmosphere which may enter the enclosure. Ex eb rated enclosures are therefore explosion protected but are not flameproof.

Clearance distances are made wider than is generally the case in industry to achieve this increased safety. Windings, mechanical strength and insulation have higher requirements that protect them from higher temperatures.

Ex ec is classed as the lowest and normal level of Ex protection, also known as reduced risk protection and for motors is non-sparking. The design aims to prevent an internal malfunction from creating sparks in normal operation and therefore is not capable of causing an explosive atmosphere to ignite. The construction ensures reliable prevention of unacceptably high temperatures and sparks or electrical arcs that could act as ignition sources in hazardous areas. It also aims to prevent excessive heating and offers a safer design against the risks of sparks during starting.

The Ex tc motor protection is designed to prevent the entry of flammable dusts into the enclosure.

Ex tb - T135C

Ex tc - T120C

Technical Data & Drawings

The wide range of HBX short cased axial fans includes over 33 models, with various configurations to suit ATEX specifications. Each IP55 motor-impeller assembly is paired with an ATEX asynchronous motor manufactured with standard voltages; 230/400V 50Hz in three phase motors up to 4kW and 400/690V 50Hz for higher powers. They are suitable for gas zone 1, 2G with Ex eb motor classification, gas zone 2, 3G with Ex ec motor classification, and dust zone 22 with ex tc or ex tb motor classifications dependent on the surface temperature required.

| Fan Type | Voltage (V) |

Frequency (Hz) |

Input Power (kW) |

Rated Current (A) |

Speed (rpm) |

Max Temp (°C) |

IP Rating (IP) |

|---|---|---|---|---|---|---|---|

| GKHM 355-CIG.102.5HF IE Gen3 (IE5) | 3~ 380-480 | 50 / 60 | 2.33 | 3.7 at 400V | 3120 | 40 | IP54 |

| GKHM 400-CIG.114.6FF IE Gen3 (IE5) | 3~ 380-480 | 50 / 60 | 4.48 | 7 at 400V | 3170 | 40 | IP54 |

| GKHM 450-CIG.128.6IF IE Gen3 (IE4) | 3~ 380-480 | 50 / 60 | 5.9 | 9.05 at 400V | 2950 | 40 | IP54 |

| GKHM 500-CIG.143.6NA IE Gen3+ (IE4) | 3~ 380-480 | 50 / 60 | 7.48 | 11.4 at 400V | 2625 | 40 | IP54 |

| GKHM 560-CIG.160.6NA IE Gen3+ (IE4) | 3~ 380-480 | 50 / 60 | 6.85 | 10.7 at 400V | 2125 | 40 | IP54 |

| GKHM 630-CIG.180.6NA IE Gen3+ (IE4) | 3~ 380-480 | 50 / 60 | 5.1 | 7.88 at 400V | 1580 | 40 | IP54 |