Cleanrooms & Containment

Minimise the introduction, generation and retention of dust and particles with

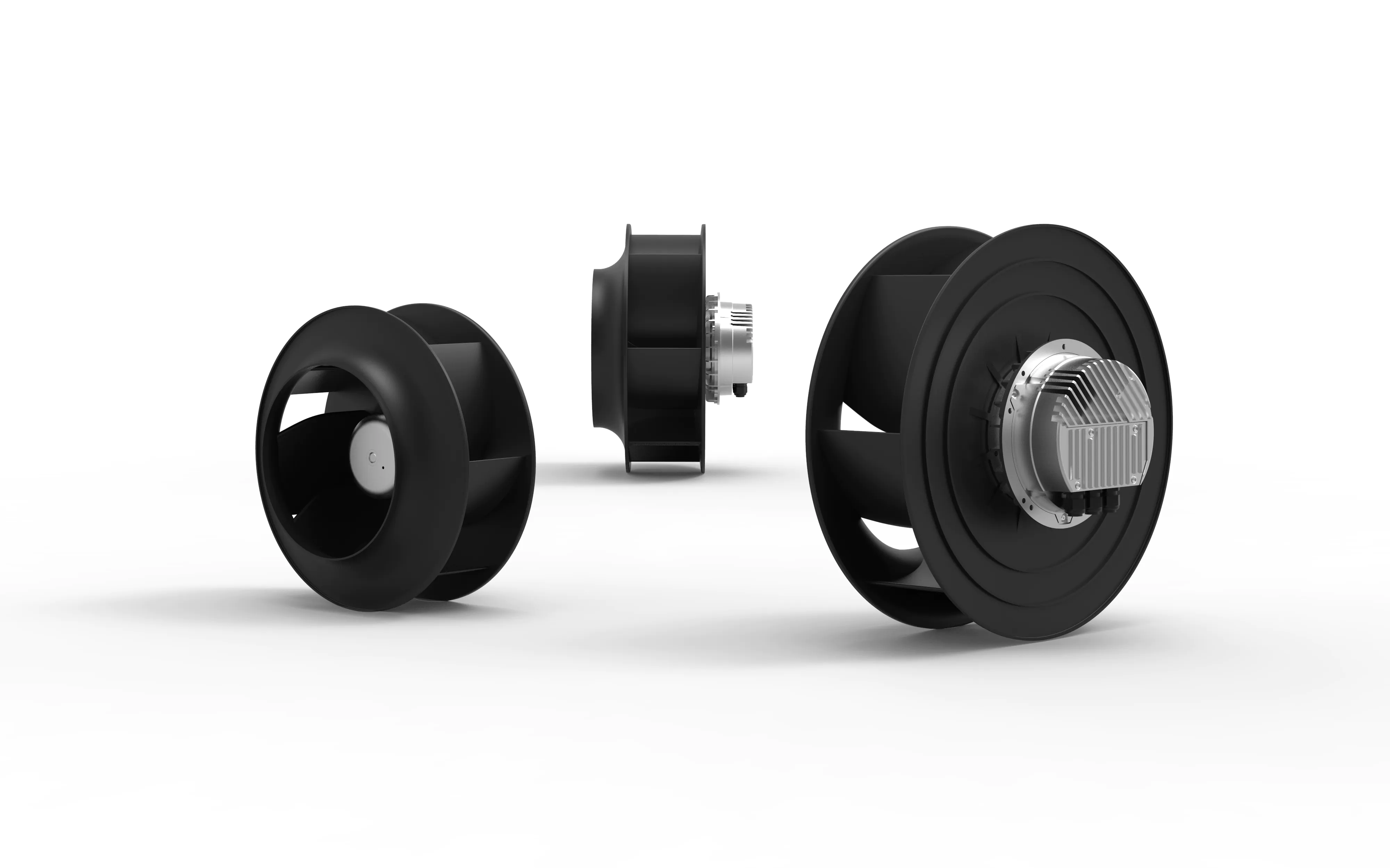

Fans for Containment & Cleanroom Ventilation Systems

Efficient EC plug fans provide the necessary pressure and airflow to adhere to the strict environment of cleanroom, containment and isolation applications. Air management and maintaining a constant air pressure using properly specified industrial fans are key aspects of providing a safe and healthy environment in cleanrooms. Cleanrooms are contained rooms with highly efficient fan filter units built into the ceiling and connected to the building ventilation system, that vacuum the air particles in the room through a set of HEPA filters. This highly precise ventilation system controls the temperature, maintains a constant air pressure and continuously cleans and filters the air to eliminate contaminants protecting staff from exposure to highly potent pharmaceutical ingredients whilst also ensuring a clean uncontaminated procedure in the case of processing.

High pressure, energy efficient plug fans, meticulously designed to

Maintain Pressure in Fan Filter Units

Pharmaceutical cleanrooms require three or four stages of HEPA filters and therefore need high pressure backward curved plug fans such as the G-Wheel EC plug fans. High performance ventilation systems ensure consistent clean air with a high air exchange rate and the correct measure of pressure, temperature and humidity. Even the smallest contaminated particle can affect product manufacturing such as powder control, so it is vital that companies are complaint, with good manufacturing practices and adhere to the classification guidelines. System and industrial plug fan specification is determined by taking into account the individual characteristics of each cleanroom set up, including the number of contaminants that are likely to be produced, the size of the particles that need to be filtered and the airflow and pressure required to remove and purify the air. The size of the room will depend on the equipment needed and the number of processes required. A fan filter unit for containment serves to generate a uniform, particle free airflow in the clean room. FFU’s allow smaller air handling units to be specified for a particular cleanroom installation, saving time and cost.