What is an External Rotor Motor?

Learn more about how outside located external rotor motors power Rosenberg and Ecofit fans.

What is an External Rotor Motor?

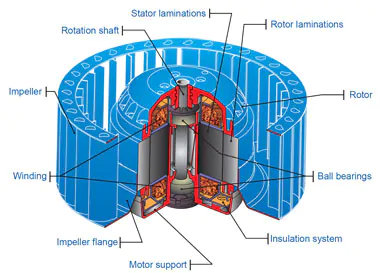

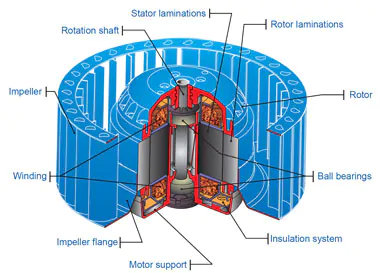

Motors come in a vast range of shapes and sizes but the internal motor is acknowledged as the standard style. The stationary component (stator) in an standard motor is fixed to the motor housing and the rotating component (rotor) is located inside the stator where it transmits torque through the output shaft. The fan impeller is attached to the rotating shaft. Unlike the standard motors whose rotors are on the inside of a wound stator, external rotor motors have their rotor on the outside. Integrating the rotor into the impeller increases the time constant of the motor which is the amount of time required for the motor to reach 63.2% of its final speed for a given voltage. This is an important measure to have in place as it prevents overheating of the motor.

External rotor motors used in motorised impellers are designed to suit the impeller they are paired which means they can match the full range of available power and speed ratings required. Therefore, external motors are more efficient in meeting performance demands. Generally, they can range anywhere between 25 W and 7,000 W and from 1,000 rpm (full rotational turns per minute) to 4,000 rpm. The speed of the motor can be controlled in various ways depending on what type of power supply the motor accepts. External rotor motors drive the majority of fans offered by our supplier partners, Ecofit and Rosenberg.